What is Laser Machine Marking

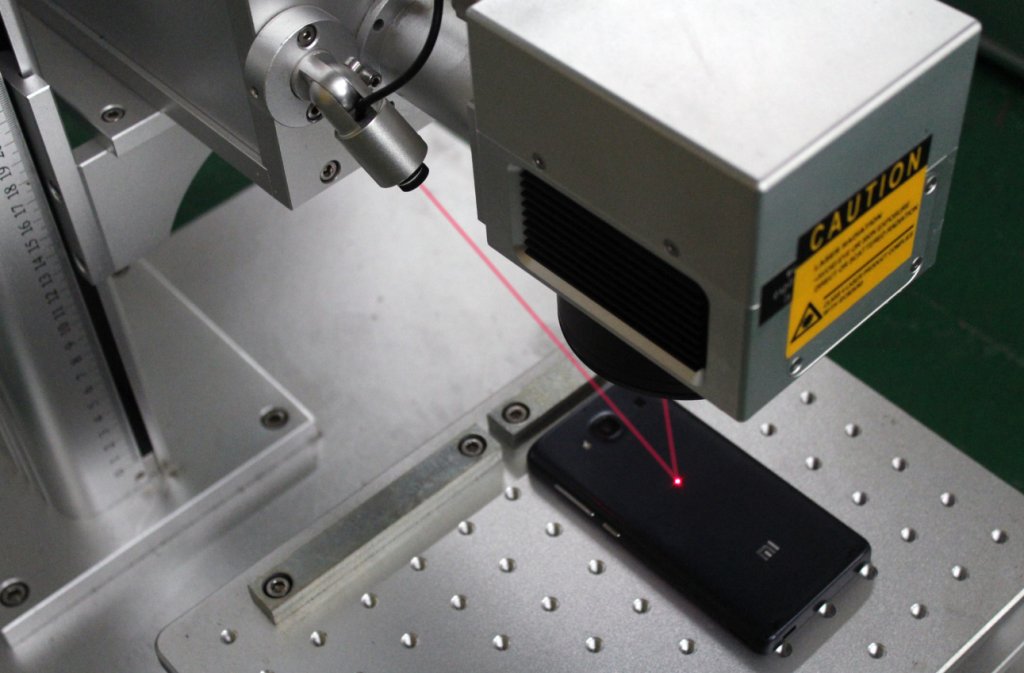

Laser machine marking, also known as laser marking, is one of the most significant applications of laser processing. This advanced technology uses high-energy density laser beams to locally irradiate workpieces, causing the surface material to vaporize or undergo color-changing chemical reactions, thereby leaving a permanent mark. Laser marking can produce various texts, symbols, and patterns, with character sizes ranging from millimeters to micrometers, which holds special significance for product anti-counterfeiting.

Basic Principles and Mechanisms

The basic principle of laser marking involves generating a high-energy continuous laser beam from a laser generator. When this laser beam interacts with the substrate material, atoms in the ground state transition to a higher energy state. These unstable high-energy atoms quickly return to the ground state, releasing excess energy in the form of photons or quanta. This energy conversion from light to heat causes the surface material to melt or even vaporize instantaneously, forming the desired graphic or textual mark.

Advantages of Laser Marking

- Non-contact Processing: Laser marking is a non-contact process that avoids mechanical stress and deformation of the workpiece, making it suitable for marking on various materials such as metals, plastics, glass, ceramics, wood, and leather.

- High Precision: Laser marking can achieve extremely fine line widths, down to 0.04mm or even smaller, ensuring high-precision marking and enhancing anti-counterfeiting capabilities.

- Durability and Permanence: The marks produced by laser marking are permanent and difficult to imitate or alter, providing strong anti-counterfeiting features.

- Cost-effective: Although the initial investment in laser marking machines is higher than traditional marking equipment, their low energy consumption, high marking speed, and ease of automation result in lower operational costs.

- Flexibility and Versatility: Laser marking machines can be controlled by software, allowing for quick adjustments to marking content. This flexibility makes them suitable for both laboratory-scale single designs and large-scale industrial production.

- Environmentally Friendly: Laser marking is a clean and pollution-free process that eliminates chemical pollution and noise pollution compared to traditional methods.

Applications Across Industries

Laser marking technology is widely used across multiple industries, from daily consumer goods to high-end manufacturing.

- Electronics Industry: Laser marking machines are used to inscribe serial numbers, production dates, brand logos, and other information on smartphones, tablets, laptops, and other electronic products. This method not only enhances product authentication and traceability but also ensures precise identification and assembly of microcomponents on circuit boards.

- Automotive Manufacturing: In the automotive industry, laser marking machines are employed to mark engine components, frames, tires, and other critical parts with high-precision serial numbers, batch numbers, and safety symbols, aiding in vehicle management, recall services, and component tracking.

- Food and Beverage Packaging: The non-contact and non-polluting nature of laser marking makes it ideal for printing dates, batch numbers, and anti-counterfeiting codes on food and beverage packaging. This technology ensures food safety and hygiene while improving production efficiency.

- Medical Devices and Biotechnology: In the medical device and biotechnology fields, laser marking machines are used to mark surgical instruments, medical consumables, and biological sample tubes with serial numbers, production dates, and usage instructions, ensuring safe use, traceability, and accurate identification.

- Jewelry and Luxury Goods: Laser marking machines are preferred for creating personalized and anti-counterfeiting marks on metal jewelry and gemstones due to their fine engraving capabilities.

Future Trends

As manufacturing moves towards cloud-based and intelligent directions, laser marking machines, as digital devices, are gradually integrating into industrial internet technology, enabling functions such as production plan management, online equipment monitoring and maintenance, and online fault diagnosis. This not only improves production efficiency and reduces costs but also brings about a new transformation in manufacturing.

In conclusion, laser machine marking, with its high precision, efficiency, and environmental friendliness, has become an indispensable processing equipment in numerous industries. As technology continues to advance, laser marking machines are expected to play a crucial role in more fields, driving the manufacturing industry towards higher quality and efficiency.