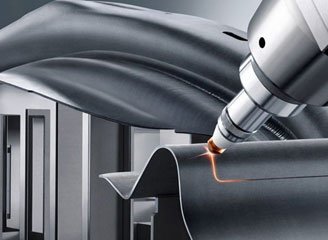

At GF Laser, 5 axis laser cutting allows us to deliver true 3D cutting with the precision and flexibility that modern automotive components demand. By processing intricate shapes, deep-drawn forms and complex angles in a single setup, we support everything from quick prototype work to reliable high-volume production.

What is 5-Axis Laser Cutting?

5 axis laser cutting is an advanced 3D laser cutting process that allows the laser head to move in multiple directions, giving manufacturers the ability to cut complex shapes that would be difficult or impossible with traditional methods. Because the cutting beam can reach the material from different angles, it delivers exceptional precision and flexibility, whether processing simple flat parts or intricate three-dimensional components. This makes 5 axis technology ideal for both prototypes and high-volume production runs, providing fast, accurate and repeatable results across a wide range of automotive applications.

Why is 5-Axis Laser Cutting Technology Used in Automotive?

5-axis allows precise trimming of stamped or drawn hydroformed parts, post-processing of hot-formed parts, cutting holes at compound angles, avoidance of secondary fixturing, and processing complex contours in one setup.

Applications in Automotive Manufacturing and Auto Parts

BIW (body in white)

5-axis laser cutting is heavily used at the BIW stage because of its ability to process complex 3D geometries after stamping or forming. Common BIW applications include:

- Trimming of stamped panels, roofs, doors, and quarter sections

- Cutting precision holes for fasteners, sensors, and alignment features

- Removing excess material from deep-drawn components

- Achieving repeatable accuracy without needing hard tooling

Chassis and suspension parts

Chassis components often require multi-directional cutting that traditional 2D lasers or mechanical methods struggle with. 5-axis laser systems support:

- Cutting and trimming welded chassis structures

- Processing control arms, subframes, and suspension housings

- Creating openings, slots, and inspection access points

Exhaust and powertrain components

Exhaust systems and powertrain parts typically involve curved surfaces, thin walls, and angles that require flexible cutting capability. Applications include:

- Laser cutting of exhaust pipes, catalytic converter housings, and heat shields

- Machining of transmission casings, engine covers, and aluminium castings

- Producing precise flange interfaces and sensor ports

Tubes and hydroformed parts

Hydroformed components are widely used for their strength-to-weight ratio but often feature complex 3D shapes. 5-axis laser cutting enables:

- Flexible trimming of hydroformed engine cradles, roof rails, and structural tubes

- Creating complex cut-outs on curved surfaces

- Reducing reliance on expensive, model-specific fixtures

Prototype and low-volume custom parts

5-axis laser cutting supports rapid design iteration and low-volume production without the need for costly bespoke tooling. Applications include:

- Quick turnaround for prototype panels and structural parts

- Cutting one-off jigs, fixtures, and motorsport components

- Supporting niche automotive builds and restoration projects

Electric vehicle components

As EV production grows, 5-axis laser cutting addresses new material challenges and component geometries. Applications include:

- Cutting battery enclosure housings and cooling plates

- Processing aluminium and lightweight structural parts

- Trimming motor housings, undertrays and sumps

Benefits of 5-Axis Laser Cut Automotive Parts

Complex Geometries & Customisation

Unlike traditional cutting methods, 5-axis laser cutting can cut holes at compound angles, avoiding secondary fixturing while also having the ability to process complex contours in one setup. It can easily follow curved surfaces, deep-drawn shapes and multi-plane components. This means holes can be cut at compound angles without additional fixtures, and complex edge profiles can be completed in a single setup. For automotive components that often feature challenging 3D geometries, this capability allows faster development, greater customisation, and consistent accuracy across both prototype and production parts.

High Precision

Precision is at the core of 5-axis laser technology. The process is ideal for trimming stamped, drawn and hydroformed parts where accuracy is essential for fit and function. It is equally effective for finishing hot-formed components made from ultra-high-strength steels, which demand clean, burr-free cutting to maintain material integrity. By delivering highly consistent edge quality, 5-axis laser cutting helps ensure that downstream assembly processes are smooth and that engineered tolerances are maintained throughout production.

Efficiency & Rapid Turnaround

One of the biggest advantages of 5-axis laser cutting is the reduction in total processing time. Because the laser can reach the workpiece from multiple angles without repositioning, entire components can often be completed in a single operation. This eliminates unnecessary handling, reduces cycle times and removes the need for expensive dedicated tooling. The result is a much faster path from design to finished part. To support customers working to tight production deadlines, we offer 24-hour laser cutting service, allowing urgent or time-critical jobs to be completed quickly and efficiently.

Our Commitment to Quality and Standards

At GF Laser, quality is embedded in every stage of our laser cutting process for the automotive industry. We operate under an accredited ISO 9001:2015 quality management system, providing full traceability, comprehensive reporting and rigorous inspection protocols throughout production.

As a trusted partner to automotive manufacturers and tiered suppliers, we fully meet the sector’s strict requirements, including the ability to supply complete Production Part Approval Process (PPAP) documentation, from design records and material certifications to process flow and capability studies.

Our dedicated Quality Department ensures every part is approved to specification and delivered on time, giving our automotive customers the confidence they need.

Our state-of-the-art 5 axis cutting system can laser cut pressings, spinnings, extrusions and tubes up to the following thicknesses:

Work With Us

5-axis laser cutting has been at the heart of GF Laser for almost two decades and with a team of highly experienced and knowledgeable estimators, 3D programmers and Operators we have become specialists within this sector.

Our work spans both volume production and premium automotive programmes, with laser cut components used in luxury models, performance cars and specialist vehicle builds. We are proud to support leading manufacturers such as Jaguar Land Rover, Aston Martin, BMW and Rolls Royce.

Our largest 5-axis laser cutting machine enables us to process automotive components up to 4 metres in length by 1.5 metres wide. Our 5-axis Trumpf laser cutting machines operate 24/7, ensuring we meet our customer’s demands. In fact, we offer one of the shortest turnaround times in the UK.