Introduction to Tube Laser Cutting Machines

In the rapidly evolving world of manufacturing, precision and speed are essential for maintaining a competitive edge. At ZLTECH Laser Machine Factory, we understand the importance of optimizing productivity without compromising on quality. One of the most revolutionary tools in modern fabrication is the Tube Laser Cutting Machine. This article explores how businesses can maximize efficiency and output using these advanced machines, while also touching on related innovations such as the Portable Laser Cleaning Machine and Laser Cleaning Machine.

Understanding Tube Laser Cutting Technology

Tube laser cutting machines utilize high-powered lasers to cut, engrave, and shape metal tubes and pipes with exceptional accuracy. Unlike traditional methods, laser cutting offers non-contact processing, which reduces wear and tear on tools and ensures smoother edges. The integration of computer numerical control (CNC) technology further enhances precision, making it possible to execute complex patterns and designs with minimal human intervention.

laser marking machine

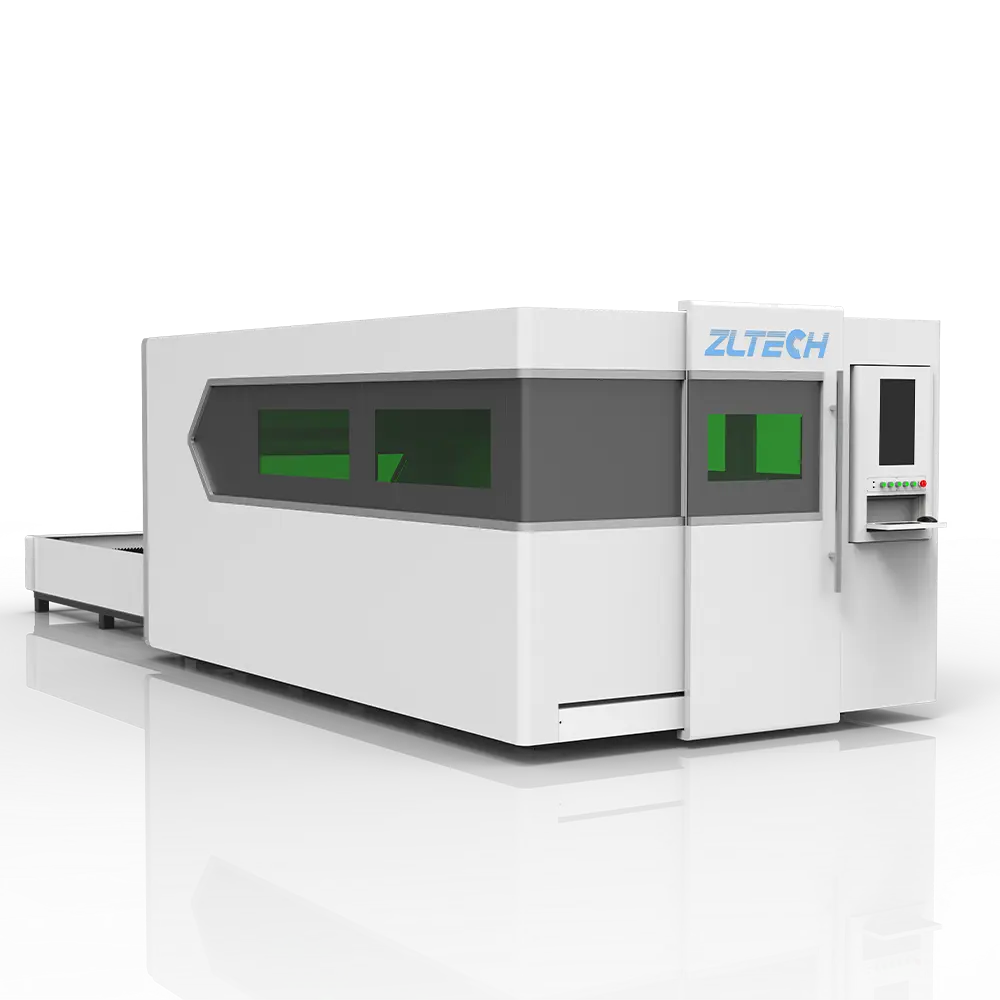

sheet and tube fiber laser cutting machine

tube laser cutting machine

tube laser cutting machine

handheld laser cleaning machine

sheet and tube fiber laser cutting machine

fiber laser marking machine

Key Features of Tube Laser Cutting Machines

- High Precision: Achieve intricate cuts with tolerances as tight as ±0.1mm.

- Speed: Significantly faster than mechanical cutting methods, boosting throughput.

- Versatility: Process a wide range of materials, including stainless steel, aluminum, and copper.

- Automation: Automated loading and unloading systems reduce manual labor and errors.

Strategies to Optimize Productivity

To fully leverage a tube laser cutting machine, manufacturers must implement effective strategies that streamline operations and minimize downtime. Below are the best practices recommended by ZLTECH Laser Machine Factory:

1. Invest in Advanced Software Integration

Modern tube laser cutting machines are equipped with intuitive software that enables seamless integration with CAD/CAM systems. By utilizing these platforms, operators can import designs directly, optimize nesting for material efficiency, and simulate cuts before production. This reduces trial-and-error, saves raw materials, and shortens lead times.

2. Regular Maintenance and Cleaning

Productivity is directly tied to machine reliability. Routine maintenance, including lens cleaning and alignment checks, prevents unexpected breakdowns. For optimal cleaning, consider using a Laser Cleaning Machine. These devices offer non-abrasive, contact-free cleaning of machine surfaces, ensuring that laser optics remain clear and efficient. For on-site and hard-to-reach areas, a Portable Laser Cleaning Machine is invaluable, allowing for quick touch-ups without dismantling equipment.

3. Train Your Workforce

A well-trained team can maximize the potential of tube laser cutting machines. ZLTECH Laser Machine Factory offers comprehensive training programs that cover machine operation, software usage, safety protocols, and basic troubleshooting. Empowering operators with knowledge not only boosts productivity but also extends the lifespan of your equipment.

4. Automate Material Handling

Automated loading and unloading systems significantly reduce cycle times. By integrating conveyors, robotic arms, or automated storage solutions, you can minimize manual intervention and streamline the workflow. This is especially beneficial for high-volume production environments where every second counts.

5. Monitor and Analyze Performance

Implementing real-time monitoring systems allows you to track key performance indicators such as cutting speed, downtime, and error rates. By analyzing this data, you can identify bottlenecks, schedule predictive maintenance, and make informed decisions to enhance productivity.

Comparing Tube Laser Cutting with Traditional Methods

| Feature | Tube Laser Cutting | Traditional Cutting |

|---|---|---|

| Precision | ±0.1mm | ±1mm |

| Speed | High | Moderate |

| Material Waste | Low | High |

| Setup Time | Minimal | Lengthy |

| Complexity of Designs | High | Limited |

Integrating Laser Cleaning for Enhanced Productivity

While tube laser cutting machines are at the forefront of fabrication technology, maintaining clean and debris-free surfaces is equally vital. Laser Cleaning Machines provide an eco-friendly and efficient solution for removing rust, paint, and contaminants from metal surfaces. Their non-contact operation ensures that delicate components are not damaged during cleaning.

For facilities requiring flexibility, a Portable Laser Cleaning Machine is a game-changer. Its lightweight design and mobility allow technicians to perform maintenance on-site, reducing downtime and ensuring that tube laser cutting machines operate at peak efficiency.

Benefits of Laser Cleaning Integration

- Extends the lifespan of cutting equipment

- Reduces the risk of defects caused by contamination

- Improves the quality of finished products

- Minimizes environmental impact compared to chemical cleaning methods

Case Study: Productivity Gains at ZLTECH Laser Machine Factory

At ZLTECH Laser Machine Factory, we implemented a comprehensive productivity optimization program. By integrating advanced tube laser cutting machines with automated material handling and regular use of laser cleaning equipment, we observed a 30% increase in output and a 25% reduction in material waste. Employee training and real-time performance monitoring further contributed to these gains, demonstrating the tangible benefits of a holistic approach.

Conclusion: The Future of Laser-Based Manufacturing

Optimizing productivity with tube laser cutting machines requires a blend of technology, training, and maintenance. By adopting the latest software, automating workflows, and ensuring cleanliness with Laser Cleaning Machine solutions, manufacturers can achieve higher efficiency, lower costs, and superior product quality. ZLTECH Laser Machine Factory remains committed to helping businesses harness the full potential of laser technology for a brighter, more productive future.

If you’re ready to take your manufacturing operations to the next level, contact ZLTECH Laser Machine Factory today to learn more about our cutting-edge tube laser cutting machines and integrated laser cleaning solutions.