Laser technology has revolutionized various industries, providing innovative solutions for cutting, engraving, and marking across a wide range of materials. From hobbyists to large-scale manufacturers, laser products are essential tools that enhance creativity and efficiency. At Mart Laser, we offer an extensive selection of high-quality laser products designed to meet the diverse needs of our customers. In this comprehensive guide, we will explore the different types of laser products, their applications, and tips for selecting the right equipment for your projects.

What Are Laser Products?

Laser products refer to a range of tools and equipment that utilize laser technology for various applications, including cutting, engraving, marking, and even medical procedures. These products come in different forms, such as laser machines, accessories, and consumables, each serving a specific purpose in the laser processing workflow.

Types of Laser Products

Understanding the different types of laser products available can help you make informed decisions based on your specific needs. Here’s a breakdown of the most common types:

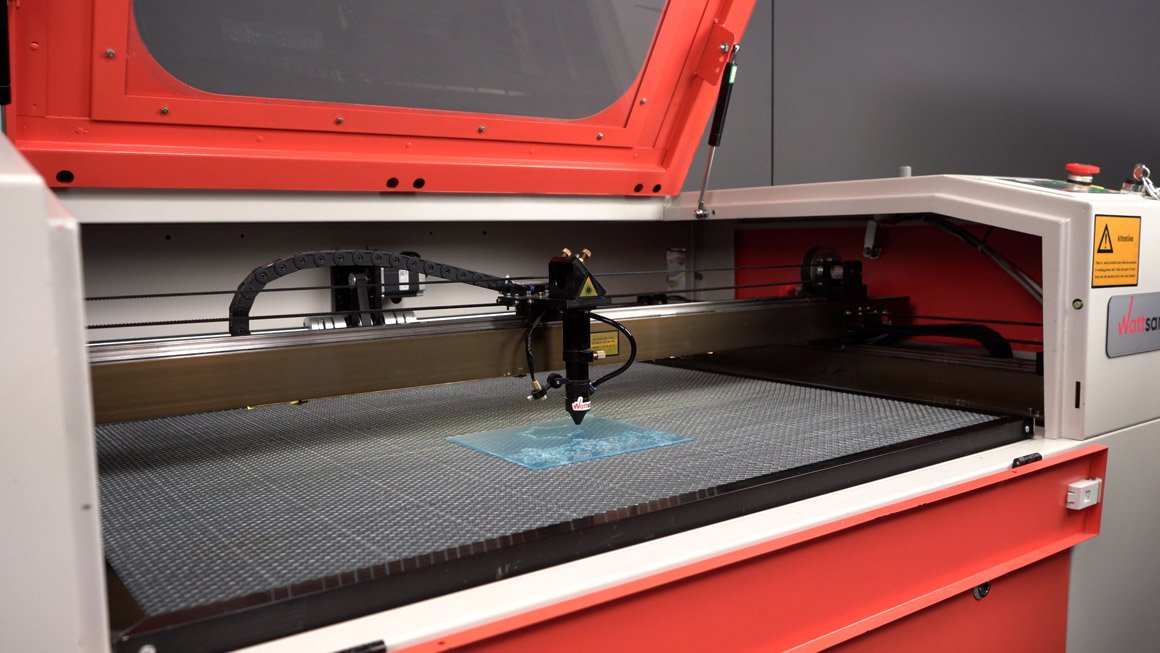

1. Laser Cutting Machines

Laser cutting machines are designed to cut through various materials with precision and speed. They are widely used in industries such as manufacturing, signage, and textiles.

- CO2 Laser Cutters: These machines use carbon dioxide lasers to cut non-metal materials like wood, acrylic, and fabric.

- Fiber Laser Cutters: Ideal for cutting metals such as steel, aluminum, and brass, fiber laser cutters offer high precision and efficiency.

2. Laser Engraving Machines

Laser engraving machines are used to etch designs, logos, and text onto various surfaces. They are commonly used for personalization and branding.

- Desktop Laser Engravers: Compact and user-friendly, these machines are perfect for small businesses and hobbyists.

- Industrial Laser Engravers: Designed for high-volume production, these machines offer advanced features and larger work areas.

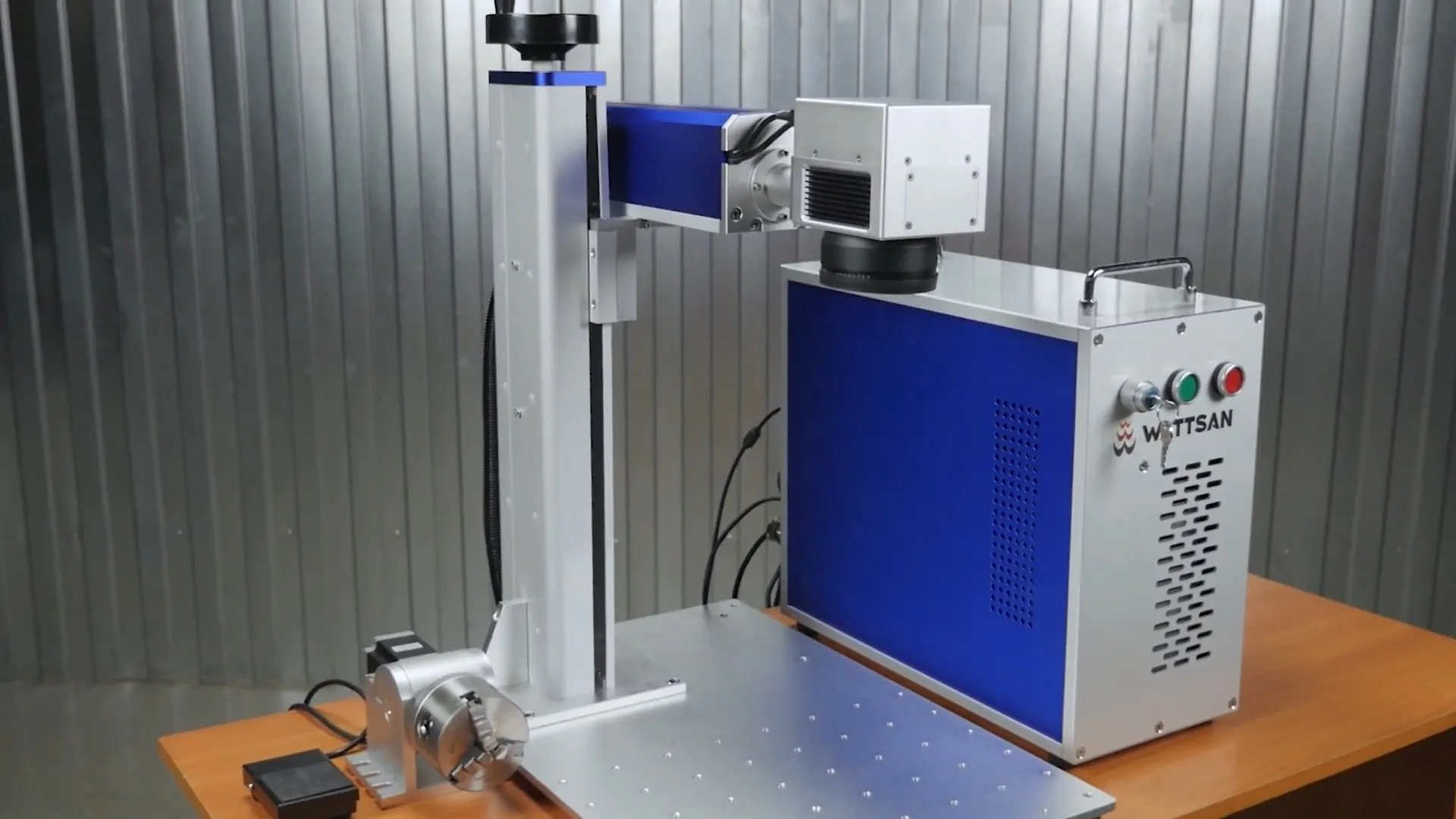

3. Laser Marking Machines

Laser marking machines are used to create permanent markings on products, such as barcodes, serial numbers, and logos. They are essential for product identification and traceability.

- Fiber Laser Markers: Known for their speed and precision, fiber laser markers are suitable for marking metals and plastics.

- CO2 Laser Markers: These machines are ideal for marking non-metal materials like wood and glass.

4. Laser Accessories

To enhance the performance of laser machines, various accessories are available:

- Lenses and Mirrors: Essential for focusing and directing the laser beam, these components are crucial for achieving optimal cutting and engraving quality.

- Cooling Systems: Maintaining the right temperature is vital for laser performance. Chillers and water pumps help regulate the temperature of laser tubes.

- Air Assist Systems: These systems blow away smoke and debris during cutting and engraving, improving the quality of the final product.

5. Laser Safety Equipment

Safety should always be a priority when working with lasers. Essential safety products include:

- Protective Eyewear: Specialized goggles are necessary to protect your eyes from harmful laser radiation.

- Fume Extractors: These devices remove hazardous fumes generated during laser cutting and engraving, ensuring a safe working environment.

Applications of Laser Products

Laser products are versatile and find applications in numerous industries. Here are some of the most common uses:

1. Manufacturing

Laser cutting and engraving are widely used in manufacturing for precise component production. Industries such as automotive, aerospace, and electronics benefit from the accuracy and speed of laser processing.

2. Signage

Laser machines are perfect for creating custom signs and displays. Whether for indoor or outdoor use, lasers can cut and engrave various materials like wood, acrylic, and metal, allowing for unique designs.

3. Personalization

From personalized gifts to custom branding, laser engraving machines enable businesses to offer unique products. Items such as jewelry, trophies, and promotional products can all benefit from laser engraving.

4. Medical Applications

In the medical field, lasers are used for precise cutting and engraving of instruments, implants, and prosthetics. Laser marking is also essential for labeling medical devices.

5. Art and Crafts

Artists and crafters use laser cutting and engraving to create intricate designs and detailed artwork. The precision of lasers allows for creative expression that would be difficult to achieve with traditional methods.

Choosing the Right Laser Products

Selecting the right laser products for your needs can be challenging. Here are some factors to consider:

1. Material Compatibility

Different laser machines are designed for specific materials. Ensure that the equipment you choose is compatible with the materials you plan to work with, whether they are wood, metal, acrylic, or fabric.

2. Machine Size and Power

Consider the size of your workspace and the scale of your projects. Larger machines may offer more capabilities but require more space. Additionally, the power of the laser will affect its cutting and engraving speed and the thickness of materials it can handle.

3. Budget

Determine your budget before making a purchase. While it’s tempting to opt for the cheapest option, investing in quality equipment can save you money in the long run through durability and efficiency.

4. Brand Reputation

Research reputable brands known for their quality and customer service. Reading reviews and testimonials can provide valuable insights into the reliability of the products.

5. Support and Training

Consider whether the manufacturer offers support and training for their products. This can be especially important for complex machinery, as proper training can enhance your productivity and efficiency.

Maintaining Your Laser Products

Proper maintenance of your laser products is essential for ensuring their longevity and optimal performance. Here are some maintenance tips:

1. Regular Cleaning

Keep your laser machine clean to prevent dust and debris from affecting performance. Regularly clean lenses, mirrors, and the work area to ensure optimal cutting and engraving quality.

2. Inspect Components

Regularly inspect all components, including lenses, mirrors, and cooling systems, for signs of wear. Replace any damaged parts promptly to avoid performance issues.

3. Monitor Software Updates

Keep your laser machine’s software up to date. Manufacturers often release updates that can improve performance and introduce new features.

4. Follow Manufacturer Guidelines

Always adhere to the manufacturer’s maintenance guidelines. This includes recommended cleaning schedules, usage tips, and safety precautions.

Conclusion

Laser products have transformed the way we create, manufacture, and personalize items across various industries. From cutting and engraving to marking and personalization, the versatility of laser technology continues to expand. At Mart Laser, we are committed to providing high-quality laser products that meet the diverse needs of our customers.

By understanding the different types of laser products available, their applications, and how to choose the right equipment, you can enhance your creative and manufacturing capabilities. Explore our extensive selection of laser products today and take your projects to the next level!