Essential Laser Machine Parts: Enhancing Performance and Precision

Laser machines are intricate systems composed of various critical parts, each playing a vital role in ensuring the machine's performance and precision. Understanding these components is essential for maintaining and optimizing laser systems for diverse applications. In this comprehensive guide, we will explore the essential parts of laser machines, their functions, and how they contribute to the overall efficiency and effectiveness of laser operations.

Key Components of Laser Machines

Laser machines consist of several key components that work together to produce, shape, and deliver laser beams with high precision and accuracy. These components include:

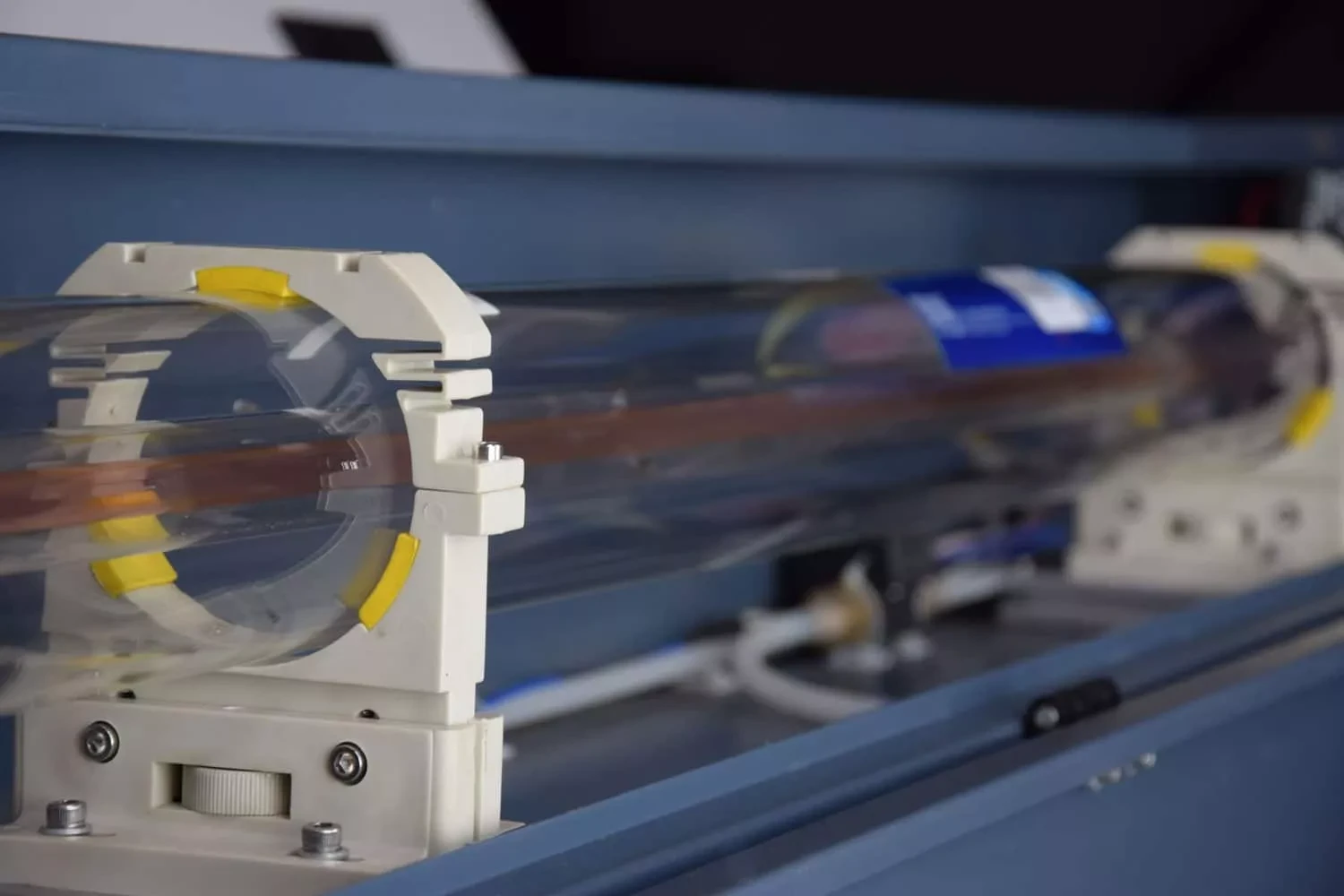

Laser Source:

- The laser source, or laser generator, is the heart of the laser machine. It generates the laser beam used for cutting, engraving, welding, or marking. The type of laser source varies depending on the application, with common types including CO2 lasers, fiber lasers, and solid-state lasers.

Laser Optics:

- Mirrors: Reflective surfaces that direct the laser beam along the desired path within the machine.

- Lenses: Focus the laser beam to a specific spot size and shape, essential for precise cutting and engraving.

- Beam Expanders: Increase the diameter of the laser beam, reducing its divergence and enhancing focus over longer distances.

- Protective Windows: Shield the laser optics from debris and contaminants, ensuring consistent performance and longevity.

Beam Delivery System:

- The beam delivery system transports the laser beam from the source to the workpiece. This system includes mirrors, lenses, and optical fibers, depending on the machine's design. Proper alignment and maintenance of the beam delivery system are crucial for optimal laser performance.

Worktable:

- The worktable, or work surface, is where the material to be processed is placed. It must be stable, flat, and precisely controlled to ensure accurate laser operations. Some worktables are equipped with automatic movement systems for enhanced efficiency and precision.

Cooling System:

- Laser machines generate significant heat during operation, which can affect performance and component lifespan. The cooling system, often water or air-based, dissipates this heat, maintaining optimal operating temperatures and preventing overheating.

Control System:

- The control system comprises the software and electronics that manage the laser machine's operations. It allows users to input design parameters, adjust settings, and monitor the process in real-time. Advanced control systems enable automation, improving accuracy and efficiency.

Motion System:

- The motion system includes motors, gears, and rails that move the laser head and worktable. Precision in movement is vital for achieving high-quality results, especially in applications requiring intricate details and tight tolerances.

Exhaust and Filtration System:

- Laser processing can produce fumes, smoke, and particulate matter that need to be safely removed from the working environment. The exhaust and filtration system extracts these byproducts, ensuring a clean and safe workspace.

Importance of Quality Laser Machine Parts

High-quality laser machine parts are essential for several reasons:

Performance and Precision:

- Superior parts ensure consistent performance and high precision, crucial for applications that demand exacting standards, such as medical device manufacturing and aerospace component fabrication.

Durability and Longevity:

- Durable components reduce the frequency of maintenance and replacements, minimizing downtime and operational costs.

Efficiency:

- Efficient parts contribute to the overall effectiveness of the laser machine, enabling faster processing times and higher throughput.

Safety:

- Reliable components enhance the safety of laser operations, protecting both the machine and its operators from potential hazards.

Maintaining and Upgrading Laser Machine Parts

Regular maintenance and timely upgrades of laser machine parts are vital for sustaining optimal performance. Here are some best practices:

Routine Inspections:

- Conduct regular inspections of all components to identify signs of wear or damage. Address issues promptly to prevent further deterioration.

Cleaning and Calibration:

- Keep optics clean and properly aligned. Regularly calibrate the machine to maintain precision and accuracy.

Replacement of Worn Parts:

- Replace worn or damaged parts with high-quality replacements to ensure continued reliable performance.

Upgrading Components:

- Consider upgrading components, such as the control system or laser source, to take advantage of technological advancements and improve machine capabilities.

Conclusion

Understanding and maintaining the essential parts of laser machines is crucial for achieving optimal performance, precision, and efficiency in various applications. High-quality components not only enhance the machine's capabilities but also ensure durability and safety. By investing in superior laser machine parts and adhering to regular maintenance practices, businesses can maximize the potential of their laser systems and achieve exceptional results.

For more information on laser machine parts and to explore our range of high-quality components, visit MartLaser.com. Our experts are here to help you find the perfect parts to enhance your laser machines and optimize your operations.

Recent Posts

Comprehensive Laser Machine Service: Ensuring Optimal Performance and Longevity

Essential Laser Machine Accessories: Maximizing Efficiency and Precision

Solid State Lasers: Revolutionizing Precision and Power in Modern Applications

Enhancing Precision: A Comprehensive Guide to Laser Lenses and Their Applications

Advancing Healthcare: A Comprehensive Guide to Laser Medical Equipment

Revolutionizing Manufacturing: A Comprehensive Guide to Laser 3D Printing Technology

The Power of Precision: A Comprehensive Guide to Laser Cleaning Technology

MARTLASER.COM, your reliable B2B2C sourcing center!

One-stop destination for all your laser shopping needs for B2B2C with great quality and competitive price.