In the ever-evolving world of industrial manufacturing, the choice of laser cutting equipment can make or break your productivity and product quality. At ZLTECH, a leading Laser Machine Factory, we understand the crucial role that power output plays in the performance of sheet metal laser cutting machines. This article explores how power output impacts cutting results, efficiency, and overall operation, helping you make informed decisions for your manufacturing needs.

Understanding Power Output in Laser Cutting Machines

Power output, measured in watts (W) or kilowatts (kW), refers to the amount of energy the laser source delivers to the material. In sheet metal laser cutting, common power outputs range from 500W to over 20kW, depending on the application and thickness of the materials being processed. Selecting the right power output is essential for achieving optimal cutting speed, precision, and edge quality.

Why Does Power Output Matter?

The power output of a laser cutting machine directly influences the interaction between the laser beam and the sheet metal. Higher power levels enable the laser to cut through thicker and denser materials, while lower power settings are suitable for thinner sheets or materials that require delicate, precise work.

sheet and tube fiber laser cutting machine

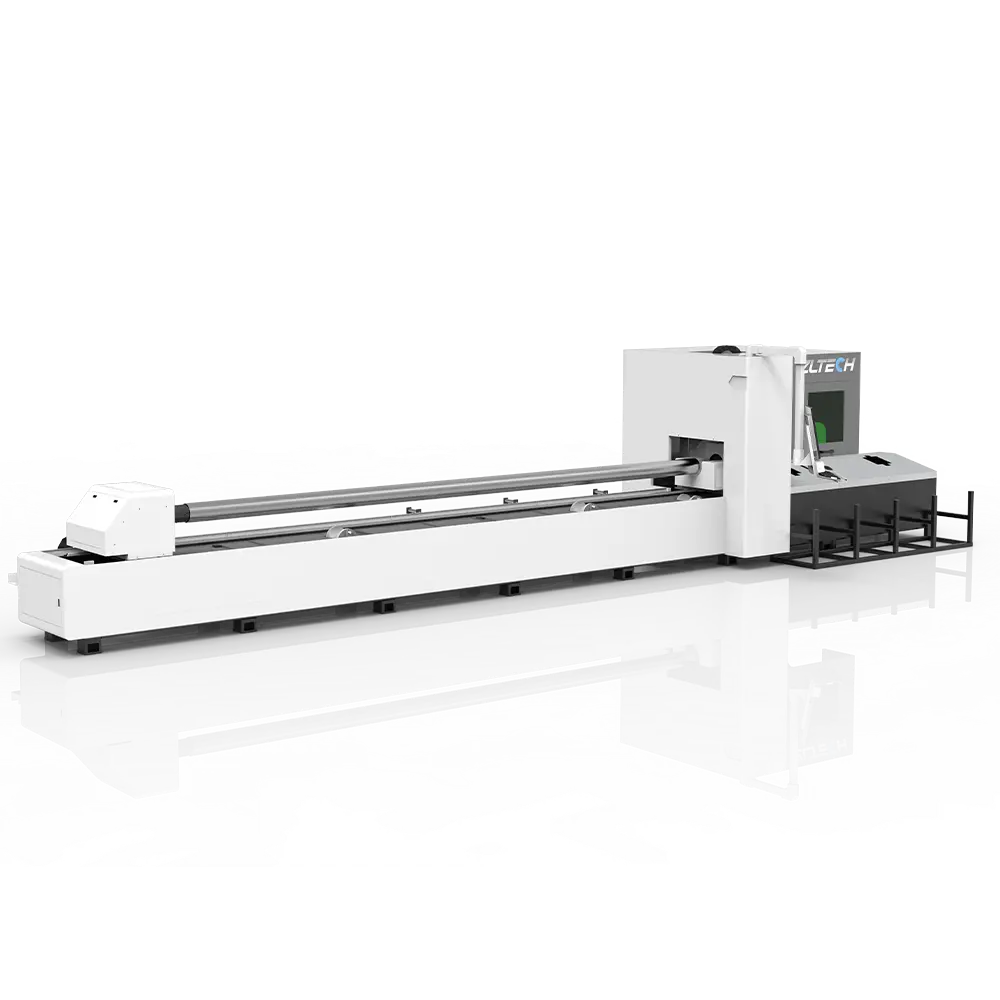

tube laser cutting machine

handheld laser welding machine

Key Effects of Power Output on Sheet Metal Cutting

1. Cutting Speed and Efficiency

One of the most significant advantages of higher power output is increased cutting speed. A more powerful laser can deliver more energy per unit time, allowing for faster material penetration and quicker completion of cutting tasks. At ZLTECH, our Laser Machine Factory engineers recommend matching the power output to your production needs for maximum efficiency.

- High Power (6kW+): Ideal for thick sheet metal (over 10mm), enabling rapid processing and reduced cycle times.

- Medium Power (2kW-6kW): Suitable for a balance of speed and precision on mid-range thicknesses (3mm-10mm).

- Low Power (<2kW): Best for thin sheets (below 3mm) and applications where fine detail is required.

2. Edge Quality and Precision

Power output also affects the quality of the cut edge. While higher power ensures faster cutting, it can sometimes introduce thermal effects such as burrs, dross, or heat-affected zones if not properly managed. Conversely, lower power settings may yield smoother, cleaner edges but at the expense of speed.

| Power Output | Edge Quality | Recommended Use |

|---|---|---|

| High | Good, but may require post-processing for thick materials | Heavy-duty industrial applications |

| Medium | Balanced, minimal post-processing | General manufacturing |

| Low | Excellent, especially for thin materials | Precision parts, prototyping |

3. Material Compatibility

Different metals and alloys respond uniquely to laser power. For example, stainless steel and aluminum require more power compared to mild steel due to their reflective and thermal properties. At ZLTECH, our laser machines are engineered to handle a wide range of materials, with adjustable power output to suit each type.

- Stainless Steel: Higher power reduces oxidation and ensures clean cuts.

- Aluminum: Requires high peak power for efficient penetration.

- Mild Steel: Can be cut efficiently with moderate power.

4. Cost and Energy Consumption

While higher power laser machines offer superior speed and versatility, they also consume more energy and may require additional cooling and maintenance. It is crucial to balance your operational costs with your production requirements. At ZLTECH, our Laser Machine Factory experts help clients select the most cost-effective solution for their specific applications.

Real-World Applications: Power Output in Action

Consider a fabrication shop that processes both thin and thick sheet metals. Investing in a high-power laser cutting machine allows the shop to tackle a broader range of projects, from intricate custom parts to heavy-duty industrial plates. However, for businesses specializing in light-gauge materials, a lower power machine may provide better precision and lower operational costs.

Case Study: ZLTECH Laser Machine Factory

At ZLTECH, our state-of-the-art Laser Machine Factory produces machines with variable power outputs to meet diverse client needs. For example, our 8kW fiber laser cutter is a popular choice for automotive and aerospace manufacturers, offering high-speed cutting with excellent edge quality. Meanwhile, our 1.5kW models are favored by electronics and signage companies for their precision and efficiency on thin metals.

Choosing the Right Power Output for Your Needs

Selecting the appropriate power output involves assessing your material types, thicknesses, desired production speed, and budget. Here are some tips from the ZLTECH Laser Machine Factory team:

- Material Thickness: Match the power to the maximum thickness you plan to cut regularly.

- Production Volume: High-volume operations benefit from higher power for faster throughput.

- Quality Requirements: For applications demanding flawless edges, consider machines with adjustable power and advanced cooling systems.

- Budget: Factor in both initial investment and ongoing energy/maintenance costs.

Integration with Automation and Smart Manufacturing

Modern sheet metal laser cutting machines, like those from ZLTECH, can be integrated with automation systems for material handling, nesting, and real-time monitoring. Higher power machines often pair well with robotic loading/unloading and Industry 4.0 solutions, maximizing efficiency and minimizing downtime.

Conclusion: Power Output Shapes Your Cutting Results

The power output of your sheet metal laser cutting machine is a critical factor that influences speed, quality, versatility, and cost. By understanding how power levels affect different aspects of cutting, you can select the optimal machine for your specific requirements. At ZLTECH Laser Machine Factory, we are committed to helping manufacturers achieve the best results with reliable, high-performance laser solutions tailored to every need.

For more information on choosing the right sheet metal laser cutting machine or to discuss your project requirements, contact ZLTECH Laser Machine Factory today. Our expert team is ready to guide you toward smarter, more efficient manufacturing solutions.