Introduction: The Importance of Choosing the Right Fiber Laser Cutter

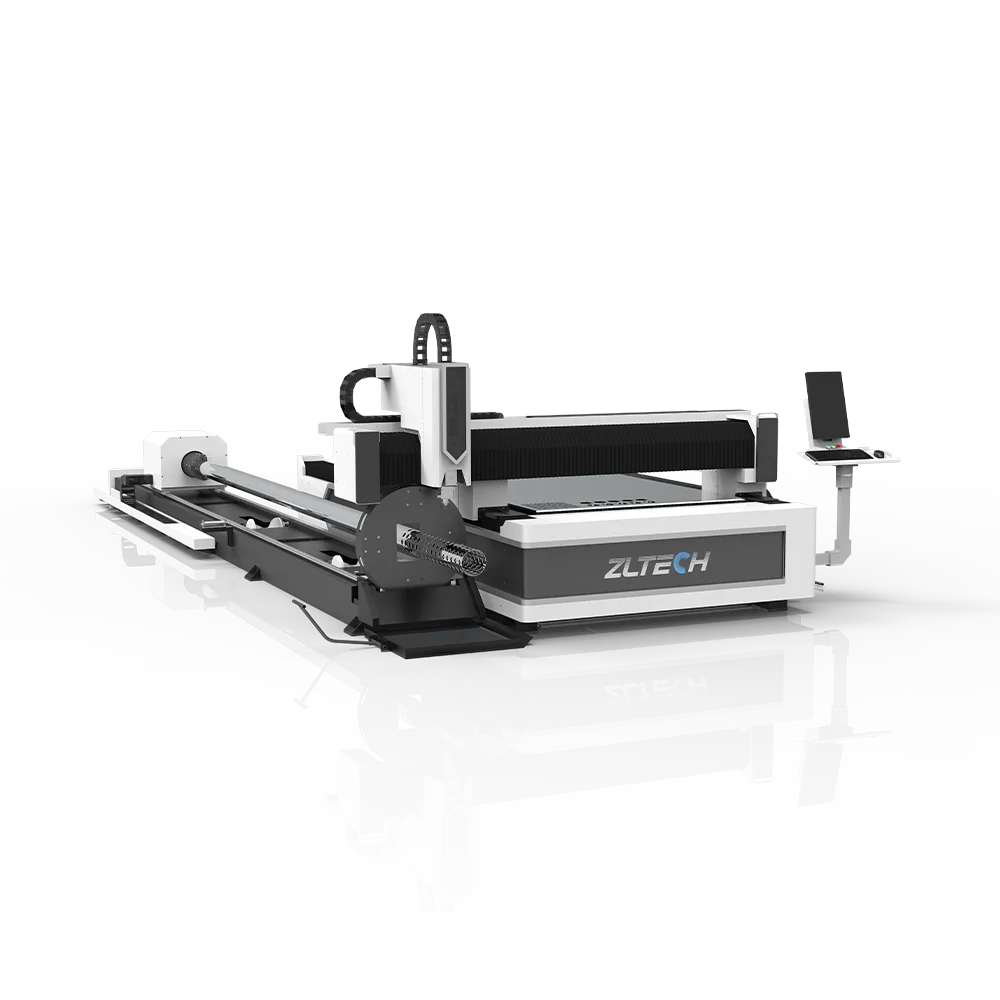

Selecting the right fiber laser cutting machine is a pivotal decision for any modern manufacturing facility. At ZLTECH, a leading laser equipment factory, we understand the impact that the right laser machine solution can have on productivity, quality, and operational costs. With the rapid advancement in laser technology, fiber laser cutters have become the backbone of metalworking, offering unparalleled precision, speed, and efficiency. But with numerous models and specifications available, how do you ensure you’re making the best choice for your factory?

Understanding Your Factory’s Needs

Assessing Production Volume and Material Types

Before diving into technical specifications, it’s crucial to evaluate your factory’s specific requirements. Consider the volume of production, the types of materials you process (such as stainless steel, aluminum, brass, or copper), and the thickness ranges involved. A laser machine solution that excels at thin sheet cutting may not be optimal for heavy plate processing. ZLTECH’s expert team recommends listing your monthly output targets and the diversity of materials to help narrow down suitable models.

Defining Cutting Quality Standards

Quality expectations differ across industries. Automotive and aerospace sectors often require precise, burr-free cuts, while general fabrication may tolerate minor imperfections. The right fiber laser cutting machine should align with your quality benchmarks, ensuring consistent results and minimizing post-processing. At our laser equipment factory, we offer machines with varying power levels and beam control features to meet diverse quality requirements.

Key Features to Consider in Fiber Laser Cutting Machines

Laser Power and Its Impact

Laser power, measured in watts, directly influences cutting speed and material thickness capabilities. Machines typically range from 500W to over 20kW. For thin metals, a 1-3kW machine may suffice, while heavy industrial applications might require 6kW or more. ZLTECH’s laser machine factory provides scalable options, ensuring you can upgrade as your production needs grow.

Cutting Bed Size and Automation Options

The size of the cutting bed determines the maximum sheet size your machine can handle. Standard beds are 3015 (3m x 1.5m), but larger formats are available for specialized tasks. Automation features, such as automatic loading/unloading, nesting software, and intelligent sensors, can dramatically boost efficiency and reduce labor costs. Our laser equipment factory offers customizable automation packages to streamline your workflow.

Control System and Software Integration

A user-friendly control system is essential for maximizing productivity. Look for machines with intuitive interfaces, real-time monitoring, and compatibility with industry-standard CAD/CAM software. ZLTECH’s fiber laser machines are equipped with advanced controllers, enabling seamless integration into your existing digital ecosystem.

Evaluating Machine Reliability and Support

Build Quality and Component Selection

Durability is non-negotiable in a high-volume laser equipment factory. Examine the build quality, focusing on frame rigidity, linear guides, and source brand (IPG, Raycus, etc.). Premium components ensure long-term accuracy and minimize downtime. ZLTECH’s machines undergo rigorous quality checks, reflecting our commitment to reliable laser machine solutions.

After-Sales Service and Technical Support

Even the best machines require maintenance and occasional troubleshooting. Choose a supplier with responsive after-sales support, comprehensive training, and readily available spare parts. ZLTECH stands out as a laser equipment factory that prioritizes customer service, offering remote diagnostics, on-site assistance, and tailored maintenance plans.

Cost Considerations and ROI Analysis

Balancing Initial Investment and Operational Savings

While the upfront cost of a fiber laser cutting machine may seem substantial, consider the long-term savings in labor, material usage, and energy consumption. High-efficiency models can slash operating expenses and boost throughput. ZLTECH’s sales engineers can help you calculate ROI, factoring in machine lifespan, productivity gains, and reduced waste.

Financing and Upgrade Paths

Flexible financing options can make advanced laser cutting technology accessible to factories of all sizes. Additionally, modular designs allow you to upgrade power sources, automation, or software as your business evolves. Our laser machine factory offers a range of purchasing and leasing plans, ensuring you’re never locked into obsolete technology.

Comparing ZLTECH Fiber Laser Cutting Machines

Product Range Overview

| Model | Power Range | Bed Size | Best For |

|---|---|---|---|

| FiberPro 3015 | 1-3kW | 3m x 1.5m | Sheet metal, general fabrication |

| FiberMax 4020 | 3-6kW | 4m x 2m | Heavy-duty, thick plate cutting |

| AutoCut Series | 6-12kW | Customizable | High-volume, automated production |

Each ZLTECH model is engineered to deliver optimal performance for specific applications, allowing you to select the perfect laser machine solution for your factory’s unique needs.

Why Choose ZLTECH as Your Laser Equipment Factory Partner?

Expertise and Innovation

With years of experience in the field, ZLTECH combines technical expertise with a passion for innovation. Our R&D team continually develops new features and enhancements, keeping your factory at the forefront of laser cutting technology.

Comprehensive Laser Machine Solutions

From initial consultation to installation and ongoing support, ZLTECH delivers turnkey laser machine solutions. Whether you need a single machine or a fully automated production line, our laser equipment factory is equipped to handle projects of any scale.

Global Reach and Local Service

ZLTECH serves clients worldwide, with local service centers and multilingual support teams. This ensures rapid response times and tailored solutions, regardless of your location.

Conclusion: Making an Informed Decision

Selecting the right fiber laser cutting machine is a strategic investment that shapes your factory’s future. Consider your production needs, quality standards, and growth plans. Partnering with a reputable laser equipment factory like ZLTECH ensures you receive not just a machine, but a comprehensive laser machine solution designed for long-term success. Contact ZLTECH today to discuss your requirements and discover how our fiber laser cutters can transform your manufacturing operations.

- Assess your factory’s material and production needs

- Evaluate machine features and automation options

- Consider reliability, support, and ROI

- Partner with ZLTECH for expert guidance and proven solutions

Ready to take your factory to the next level? Explore ZLTECH’s full range of fiber laser cutting machines and experience the difference a leading laser equipment factory can make.

Tags:Sheet Metal Laser Cutting Machine,laser machine solution,CNC Hydraulic Press Brake