Laser Cleaning Metal:

In the realm of industrial maintenance, cleanliness is a critical factor that determines the efficiency, longevity, and overall performance of machinery and equipment. Traditional cleaning methods, such as mechanical brushing, sandblasting, and chemical treatments, have been the go-to solutions for decades. However, with the advent of laser cleaning technology, a new era of precision, efficiency, and sustainability has dawned in the world of metal cleaning. This blog post explores the fascinating world of laser cleaning metal and its transformative impact on industrial processes.

What is Laser Cleaning?

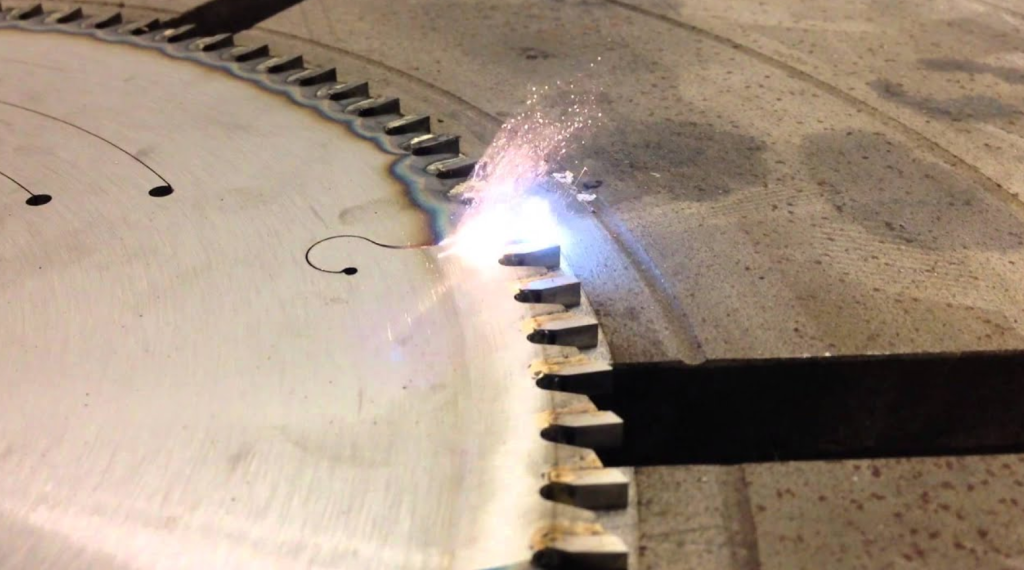

Laser cleaning is a non-contact, non-abrasive process that utilizes high-energy laser beams to remove contaminants from metal surfaces. The intense heat generated by the laser vaporizes the contaminants, which are then carried away by air currents or suction systems. This gentle yet effective method ensures that the underlying metal surface remains intact and unharmed.

The Advantages of Laser Cleaning Metal

- Precision and Control:

The laser beam can be focused to an extremely small spot, allowing for highly precise cleaning of intricate designs and tight spaces. This precision is invaluable in industries where the tolerance for error is minimal, such as aerospace and precision machining. - Speed and Efficiency:

Laser cleaning is significantly faster than traditional methods, which means less downtime and higher productivity. The laser beam can scan large surfaces rapidly, removing contaminants in a fraction of the time it would take with manual cleaning techniques. - Sustainability:

Unlike chemical cleaning methods, laser cleaning doesn’t produce harmful waste or emissions. It’s a dry process that requires no consumables, making it a more environmentally friendly option. This is particularly important in today’s world, where sustainability is a top priority for businesses and consumers alike. - Cost Savings:

Over time, laser cleaning can lead to significant cost savings. By reducing the need for consumables, minimizing waste disposal costs, and extending the lifespan of metal surfaces through gentler cleaning methods, laser cleaning offers a cost-effective alternative to traditional cleaning techniques. - Versatility:

Laser cleaning is effective on a wide range of metals, including stainless steel, aluminum, titanium, and brass. It can remove a variety of contaminants, from light oils and greases to heavy rust and coatings, making it a versatile solution for a multitude of industrial applications.

Applications in Various Industries

Laser cleaning technology is finding a wide range of applications across various industries:

- Aerospace:

In the aerospace industry, precision is paramount. Laser cleaning is used to remove contaminants from critical surfaces, such as those on aircraft engines and structural components, ensuring that they perform optimally and safely. - Automotive:

Manufacturers in the automotive industry use laser cleaning to prepare metal surfaces for painting, ensuring a smooth, even finish. It’s also used to remove rust and corrosion from engine components, extending their lifespan and reducing maintenance costs. - Precision Machining:

In precision machining, laser cleaning ensures that surfaces are free of contaminants before welding, brazing, or coating processes. This enhances the quality and reliability of the final product, making it a critical step in the manufacturing process. - Art Restoration:

Laser cleaning is also finding applications in the art restoration field, where it’s used to gently remove dirt, grime, and coatings from historical artifacts and works of art, preserving their original integrity and beauty.

The Future of Laser Cleaning Metal

As laser technology continues to evolve, we can expect to see even greater advancements in laser cleaning metal. The development of more powerful, efficient, and compact laser systems will expand the range of applications and make laser cleaning accessible to even more industries. Researchers are also exploring new wavelengths and pulse durations to optimize the cleaning process for different metals and contaminants.

Conclusion

Laser cleaning metal is a revolutionary advancement in industrial maintenance that offers a multitude of benefits over traditional cleaning methods. Its precision, speed, sustainability, cost savings, and versatility make it an ideal solution for maintaining the cleanliness and integrity of metal surfaces across a wide range of industries. As the technology continues to develop, we can look forward to even more innovative and efficient cleaning solutions that will further enhance industrial processes and productivity. For businesses seeking to improve their cleaning processes, investing in laser cleaning technology could be the key to unlocking new levels of efficiency, quality, and sustainability.