LCOS devices are driven by AC voltage, which can induce flickering caused by oscillation of liquid crystal molecules. While flicker may be negligible in visual applications, it can severely impact high-precision optical systems. Our SLM reduces flicker by operating at drive frequencies above 1 KHz. It also supports video signal input via a digital visual interface (DVI) and allows phase pattern storage (up to 128 patterns) via universal serial bus (USB) to enable fast switching with external systems using trigger input/output functions. A software development kit (SDK) is available for user-side control via custom programs.

LCOS-based SLM applications

While LCOS-based SLMs are fundamentally phase modulation devices, they have diverse applications—ranging from holographic AR/VR displays to adaptive optics in microscopy and astronomy, and mode conversion in optical communications.

Traditionally, these applications involve relatively low-power lasers. Although LCOS-based SLMs can perform beam shaping for laser processing, their damage threshold had been a limiting factor. But improvements in laser resistance opened the door to their use in high-power laser applications such as metal processing. Unlike conventional systems that require hardware reconfiguration for each task, SLMs enable dynamic, real-time beam shaping—and offer major advantages for precision microfabrication and complex geometry welding/cutting.

Unlocking new frontiers: 1-kW power-handling LCOS-based SLMs

Cutting and welding metal materials typically require lasers with powers exceeding 1 kW. Proper beam shaping can reduce spatter and improve processing quality. To achieve it using an LCOS-based SLM, the device must endure high laser powers. Santec’s SLM-310 offers true 1-kW power handling, which makes it suitable for direct use within demanding laser processing environments.

Optimizing the beam profile during processing enhances thermal efficiency, enables faster cutting, higher-precision welding, and more intricate microfabrication. Complex shapes that were difficult to process before can now be manufactured rapidly and with high precision—and it opens new possibilities for aerospace, automotive, medical, and semiconductor fields.

Advantages of LCOS SLMs with 1-kW power handling

Galvo mirrors are widely used for laser processing to scan the beam by varying angles along x and y axes, but the scanning process is time-consuming. In contrast, LCOS-based SLMs can perform one-shot processing via computer-generated holograms (CGHs)4 to significantly reduce the processing time.

Compared to DLPs, LCOS-based SLMs offer higher phase stability, which makes them better suited for CGH-based processing. Diffractive optical elements (DOEs) can also shape beams, but require physical replacement for different patterns—and this increases the setup time. LCOS-based SLMs allow programmable beam shaping without mechanical adjustments, which enables greater flexibility and efficiency within manufacturing environments.

Evolution of LCOS for NIR laser processing

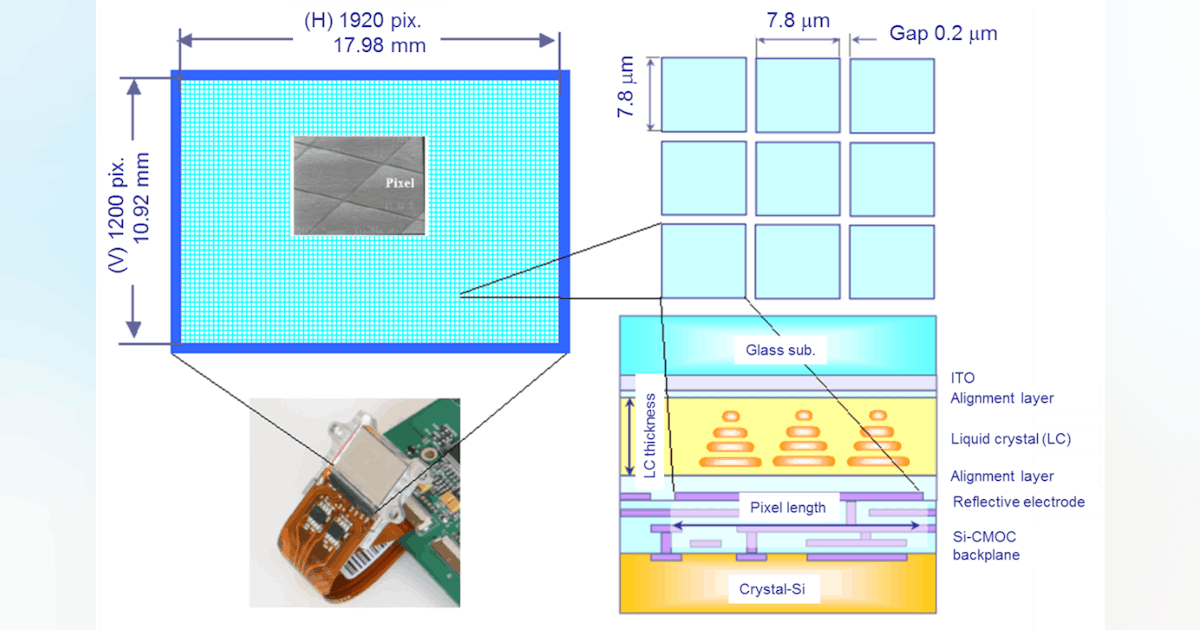

Conventional LCOS devices, designed for human-viewable displays, were not built to withstand hundreds or thousands of watts of laser power. Exposure to high-power lasers could irreversibly damage various internal components (see Fig. 3), including the cover glass, alignment layer, electrodes, mirrors, and liquid crystals.