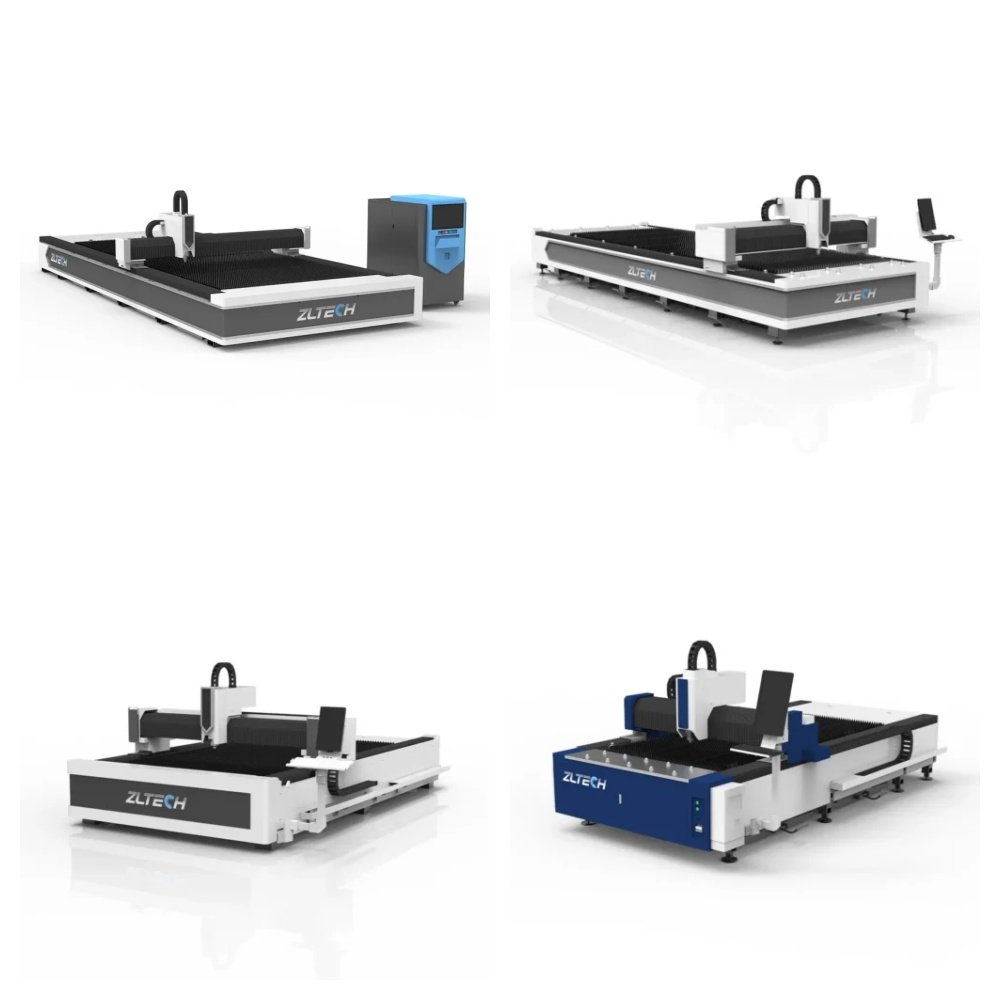

Sheet Metal Laser Cutting Machine with Innovative Software Integration: ZLTECH Laser Machine Factory Leading the Future

In the dynamic world of manufacturing, the demand for precision, speed, and efficiency has never been higher. As industries evolve, so does the need for advanced machinery that can keep up with complex production requirements. ZLTECH, a renowned name in the laser machine sector, stands at the forefront of this evolution. At their state-of-the-art Laser Machine Factory, ZLTECH develops cutting-edge sheet metal laser cutting machines that not only deliver superior performance but also integrate the latest software innovations to revolutionize the manufacturing process.

The Rise of Sheet Metal Laser Cutting Machines

Sheet metal laser cutting machines have transformed the fabrication industry by offering unmatched accuracy and flexibility. Unlike traditional cutting methods, laser technology enables manufacturers to create intricate designs with minimal waste and maximum efficiency. ZLTECH’s commitment to technological advancement has propelled their Laser Machine Factory to the forefront, delivering machines that cater to a wide array of industries, from automotive to aerospace.

- High precision for complex geometries

- Minimal material wastage

- Fast turnaround times

- Reduced production costs

Innovative Software Integration: The ZLTECH Advantage

What truly sets ZLTECH apart is their focus on software integration within their sheet metal laser cutting systems. Modern manufacturing isn’t just about hardware; it’s about creating a seamless interface between machine and operator. ZLTECH’s proprietary software platform introduces a new level of intelligence to the cutting process, featuring real-time monitoring, automated adjustments, and intuitive user interfaces.

Key Features of ZLTECH’s Software Integration

- Real-Time Monitoring: Operators can oversee every stage of the cutting process, ensuring optimal performance and immediate issue detection.

- Automated Adjustments: The system automatically tweaks parameters such as speed, power, and focus based on material type and thickness, reducing the margin for error.

- Remote Access and Cloud Connectivity: Managers can access production data and machine status from anywhere, enabling proactive maintenance and data-driven decision-making.

- User-Friendly Interface: The software is designed for ease of use, minimizing training time and maximizing productivity.

These features make ZLTECH’s sheet metal laser cutting machines a preferred choice for businesses looking to stay ahead of the curve. By integrating smart software solutions, the Laser Machine Factory ensures that every machine delivers consistent, high-quality results with minimal human intervention.

Benefits of Sheet Metal Laser Cutting with ZLTECH

The integration of advanced software into laser cutting machines brings significant advantages:

| Benefit | Description |

|---|---|

| Precision | Software algorithms ensure exact cuts, even on complex shapes. |

| Efficiency | Automated processes reduce cycle times and increase throughput. |

| Flexibility | Quickly switch between different materials and designs without manual recalibration. |

| Cost Savings | Less waste and reduced labor requirements lower overall production costs. |

| Data Insights | Cloud-based analytics offer insights for continuous improvement. |

With these benefits, it’s clear why ZLTECH’s sheet metal laser cutting machines are a staple in modern manufacturing facilities.

Laser Machine Factory: A Hub of Innovation

At the heart of ZLTECH’s success is their Laser Machine Factory. This facility is where cutting-edge engineering meets practical application. Every machine is assembled with meticulous attention to detail, ensuring reliability and longevity. The factory is also a testing ground for new software features, allowing ZLTECH to stay ahead in the rapidly evolving world of industrial automation.

- Continuous R&D investments

- Rigorous quality control processes

- Collaboration with industry leaders

- Customizable solutions for unique customer needs

The Laser Machine Factory is not just a production site; it’s an innovation hub where the future of sheet metal processing is being shaped.

Industry Applications and Case Studies

ZLTECH’s sheet metal laser cutting solutions are widely used across various industries. In the aerospace sector, precision and consistency are paramount. ZLTECH machines deliver the tight tolerances required for critical components. In the automotive industry, the flexibility to handle different metals and thicknesses allows manufacturers to quickly adapt to changing design specifications.

One notable case study involves a leading electronics manufacturer, who leveraged ZLTECH’s smart software to reduce downtime by 30% and improve yield by 15%. The ability to monitor machine status remotely and receive predictive maintenance alerts was a game-changer for their production line.

Future Trends: AI and IoT in Laser Cutting

As the manufacturing landscape continues to evolve, ZLTECH is already exploring the integration of AI (Artificial Intelligence) and IoT (Internet of Things) technologies into their laser cutting systems. AI-driven analytics can further optimize cutting paths and predict maintenance needs, while IoT connectivity ensures seamless communication between machines and enterprise systems.

These advancements will enable factories to achieve even higher levels of automation, efficiency, and quality control—solidifying ZLTECH’s position as a leader in the industry.

Conclusion: Why Choose ZLTECH’s Sheet Metal Laser Cutting Machines?

In summary, the combination of robust hardware and innovative software integration makes ZLTECH’s sheet metal laser cutting machines a top choice for modern manufacturers. The Laser Machine Factory’s dedication to excellence ensures each machine is built to last and ready to tackle the challenges of tomorrow. Whether you’re looking to improve productivity, reduce costs, or stay ahead of technological trends, ZLTECH delivers solutions that set new industry standards.

For businesses seeking to revolutionize their metal fabrication processes, partnering with ZLTECH and their Laser Machine Factory is a step towards a smarter, more efficient future.

Tags:laser machine manufacturer,Portable Laser Cleaning Machine