In the rapidly evolving world of industrial automation, businesses are constantly seeking innovative methods to improve efficiency, precision, and productivity. ZLTECH Laser Machine Factory stands at the forefront of this revolution, offering state-of-the-art Tube Laser Cutting Machines designed to meet the diverse needs of modern manufacturing. In this article, we explore the compelling reasons to choose a tube laser cutting machine from ZLTECH for your industrial automation requirements.

The Rise of Tube Laser Cutting Machines in Automation

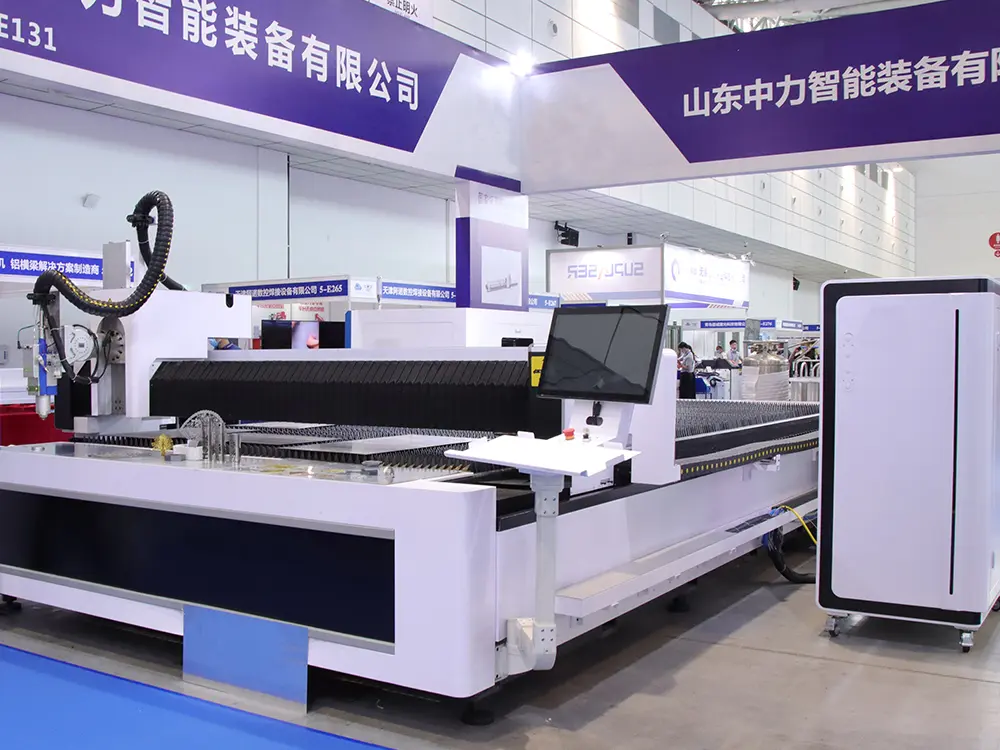

Tube laser cutting machines have transformed the way industries handle metal fabrication and component manufacturing. Unlike traditional cutting processes, these advanced machines utilize high-powered lasers to deliver unmatched speed and accuracy. As a result, manufacturers can now achieve complex cuts and intricate designs that were previously impossible or cost-prohibitive.

- Increased efficiency and reduced production time

- Enhanced accuracy and consistency in every cut

- Minimal material wastage and lower operational costs

At ZLTECH Laser Machine Factory, our commitment to innovation ensures that our tube laser cutting machines are equipped with the latest technology, making them an indispensable tool for industrial automation.

Key Advantages of ZLTECH Tube Laser Cutting Machines

1. Superior Precision and Quality

One of the most significant benefits of tube laser cutting machines is their ability to deliver precise and clean cuts. ZLTECH’s machines use advanced laser technology to ensure that every cut meets exact specifications, regardless of the complexity of the design. This precision is crucial for industries such as automotive, aerospace, and construction, where high-quality components are essential.

2. Enhanced Productivity and Flexibility

With ZLTECH tube laser cutting machines, manufacturers can automate cutting processes and handle large volumes of work with minimal human intervention. The flexibility of these machines allows for quick changeovers between different tube shapes and sizes, catering to a wide range of applications. This adaptability is vital in today’s fast-paced manufacturing environment.

3. Cost-Effective Operation

By integrating tube laser cutting machines into your production line, you can significantly reduce labor costs and material wastage. The precise nature of laser cutting minimizes errors, leading to fewer rejected parts and lower raw material consumption. Over time, this translates into substantial cost savings for your business.

4. Safety and Reliability

ZLTECH Laser Machine Factory prioritizes the safety and reliability of its equipment. Our tube laser cutting machines are designed with advanced safety features and robust construction, ensuring safe operation and long-term durability. This reliability minimizes downtime, further boosting your productivity.

Applications Across Diverse Industries

The versatility of tube laser cutting machines makes them suitable for a wide array of industries. From creating intricate metal frameworks for furniture to manufacturing structural components for heavy machinery, ZLTECH’s machines deliver consistent results every time.

- Automotive: Precision cutting for exhaust systems, chassis, and body frames

- Construction: Custom structural components and architectural designs

- Furniture: Artistic and functional metal frameworks

- Shipbuilding and Aerospace: Lightweight yet strong components

Our customers consistently report improved product quality and faster turnaround times after integrating ZLTECH tube laser cutting machines into their production lines.

Integrating Tube Laser Cutting Machines with Sheet Metal Laser Cutting Machine

For manufacturers looking to further enhance their capabilities, combining tube laser cutting machines with a sheet metal laser cutting machine can be a game-changer. While tube laser cutting machines excel at processing cylindrical and square tubes, sheet metal laser cutting machines are designed for flat metal sheets. Together, they enable complete fabrication solutions under one roof, reducing outsourcing and streamlining production.

- Seamless transition between tube and sheet cutting tasks

- Increased versatility for custom projects

- Optimized workflow and reduced lead times

ZLTECH Laser Machine Factory offers integrated solutions and expert support to help you maximize the potential of both tube and sheet metal laser cutting technologies.

The Role of Fiber Laser Cutting Machine in Modern Manufacturing

Another significant advancement in the field is the fiber laser cutting machine. Unlike traditional CO2 lasers, fiber lasers offer greater energy efficiency, faster cutting speeds, and the ability to handle a wider range of materials. ZLTECH’s fiber laser cutting machines complement our tube laser solutions, providing manufacturers with the flexibility to tackle even the most demanding projects.

- High-speed cutting for thin and thick materials

- Low maintenance and operational costs

- Exceptional edge quality and minimal heat distortion

By incorporating both tube and fiber laser cutting machines, manufacturers can stay ahead of the competition and meet the evolving demands of the market.

Why Trust ZLTECH Laser Machine Factory?

Choosing the right equipment partner is as important as selecting the right technology. ZLTECH Laser Machine Factory is renowned for its commitment to quality, innovation, and customer satisfaction. Our team of experts works closely with clients to understand their unique requirements and provide tailored solutions that drive success.

| Feature | ZLTECH Advantage |

|---|---|

| Cutting Precision | ±0.1mm accuracy with minimal burrs |

| Automation | Seamless integration with smart factory systems |

| Support | 24/7 technical assistance and training |

| Customization | Machines tailored to specific industry needs |

Future-Proof Your Business with ZLTECH

As industries continue to embrace automation and digital transformation, investing in advanced manufacturing equipment is no longer optional—it’s essential. Tube laser cutting machines from ZLTECH Laser Machine Factory provide the technological edge you need to remain competitive, efficient, and responsive to market demands.

Whether you’re upgrading your current production line or building a new facility, our team is ready to help you choose the perfect solution for your business. With ZLTECH, you gain a reliable partner committed to your long-term success.

Conclusion

Tube laser cutting machines are revolutionizing industrial automation by offering unmatched precision, efficiency, and versatility. When combined with other technologies such as sheet metal laser cutting machines and fiber laser cutting machines, they unlock new possibilities for manufacturers across various sectors. Choose ZLTECH Laser Machine Factory for cutting-edge solutions, expert support, and a partnership that drives your business forward.

Ready to take your manufacturing to the next level? Contact ZLTECH Laser Machine Factory today to learn more about our tube laser cutting machines and how they can transform your industrial automation processes.