Why Is Energy Efficiency Vital in Sheet Metal Laser Cutting Machine Usage?

Introduction: The Role of Energy Efficiency in Modern Manufacturing

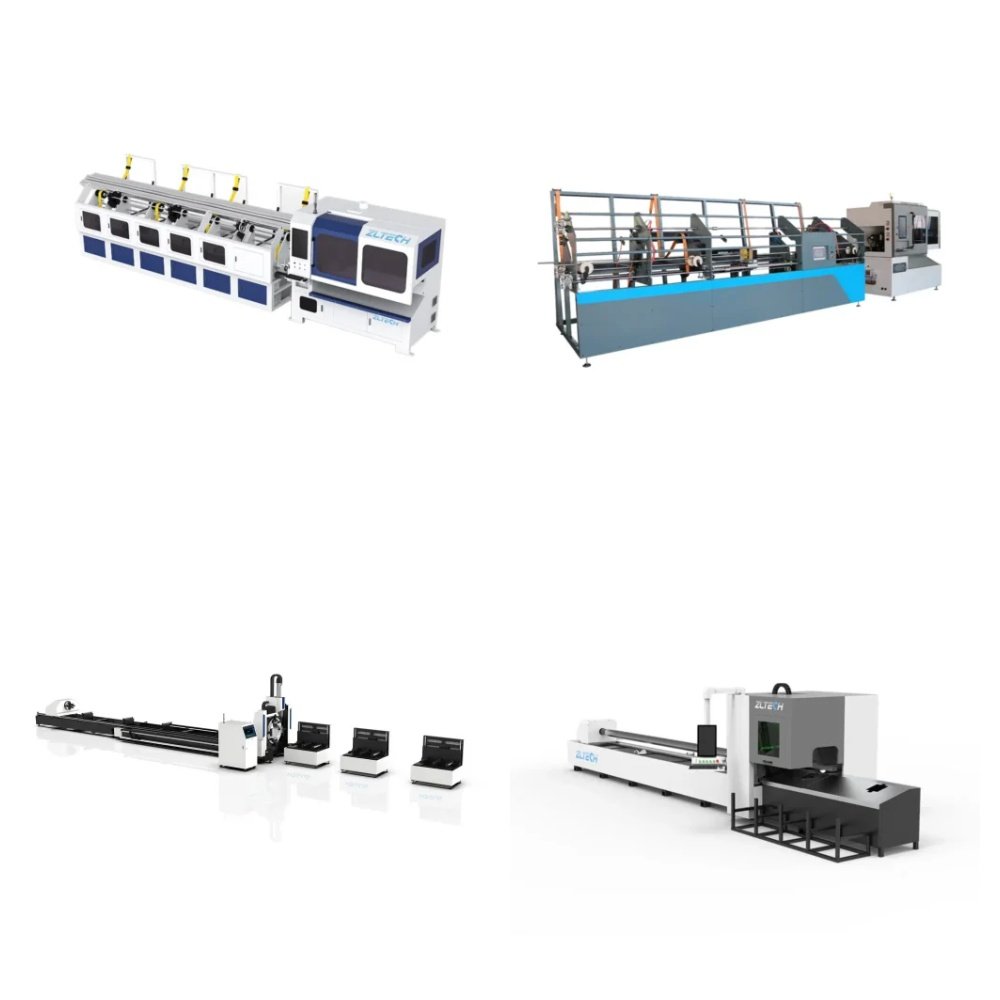

In the competitive world of manufacturing, energy efficiency has become a cornerstone for sustainability and cost management. For industries relying on precision and speed, such as sheet metal processing, the choice of machines and operational practices can have a profound impact on both environmental footprint and operational expenses. At ZLTECH, a leading Laser Machine Factory, we recognize the pivotal role energy efficiency plays in sheet metal laser cutting machine usage. This article explores why energy efficiency is vital, how it impacts manufacturing, and how our solutions address these evolving needs.

Understanding Sheet Metal Laser Cutting Machines

Sheet metal laser cutting machines are advanced tools designed to cut, engrave, and shape metals with high precision. The technology relies on a focused laser beam that melts, burns, or vaporizes the material, resulting in clean and accurate cuts. These machines are widely used in industries such as automotive, aerospace, electronics, and construction due to their ability to handle complex designs and various thicknesses.

However, the process demands considerable energy, especially when cutting thick or highly reflective metals. This is where energy efficiency becomes a key consideration—not only to reduce costs but also to align with global sustainability goals.

The Importance of Energy Efficiency in Sheet Metal Laser Cutting

- Cost Savings: Energy-efficient laser cutting machines use less electricity, directly reducing operational costs. Over time, these savings can be substantial, particularly for factories running multiple machines or operating around the clock.

- Environmental Impact: Lower energy consumption translates to reduced carbon emissions. For manufacturers committed to green practices, investing in energy-efficient equipment is crucial for minimizing their environmental footprint.

- Enhanced Productivity: Efficient machines often operate faster and with greater precision, maximizing throughput without compromising quality. This leads to shorter lead times and increased customer satisfaction.

- Compliance with Regulations: Many regions now enforce strict energy and emission standards. Energy-efficient machinery helps companies meet these regulations, avoiding penalties and supporting brand reputation.

How ZLTECH Laser Machine Factory Leads in Energy Efficiency

At ZLTECH, we have dedicated our research and development to creating laser cutting machines that excel in energy efficiency. Our models are equipped with advanced fiber laser technology, which is renowned for its low power consumption and high conversion efficiency. This technology ensures that more of the electrical energy is converted into usable laser output, minimizing waste and maximizing performance.

Additionally, our machines feature intelligent control systems that optimize energy use based on the thickness and type of metal being processed. This adaptive approach not only saves power but also extends the lifespan of critical components, reducing maintenance costs.

Latest Innovations in Energy-Efficient Laser Cutting

The landscape of laser cutting is constantly evolving, with new innovations aimed at further improving energy efficiency. For example, the integration of IoT (Internet of Things) sensors allows real-time monitoring of energy consumption, enabling operators to adjust settings for optimal performance. Automated shutdown and standby modes also contribute to energy savings by ensuring machines only use power when necessary.

At ZLTECH Laser Machine Factory, we embrace these advancements, offering machines that not only deliver superior cutting quality but also help our clients achieve their sustainability targets.

Case Study: Energy Efficiency in Action

A recent client in the automotive sector upgraded their production line with ZLTECH’s energy-efficient laser cutting machines. The results were immediate: a 25% reduction in electricity consumption, improved cutting speeds, and enhanced product quality. The company also reported easier compliance with local environmental regulations, thanks to their lower energy usage and reduced emissions.

This case highlights how investing in energy-efficient solutions can yield tangible benefits across multiple dimensions of manufacturing performance.

Integrating Automation and Sheet Metal Laser Cutting

Automation is another key trend in the laser cutting industry. By integrating automated material handling systems with energy-efficient laser machines, manufacturers can further reduce waste and enhance process reliability. Automation ensures that machines operate at optimal settings, reducing idle times and unnecessary energy use.

At ZLTECH, we offer customizable automation solutions that seamlessly integrate with our laser cutting machines, supporting smarter manufacturing and greater energy savings.

Keyword Focus: Fiber Laser Cutting Machine & Laser Cutting Machine Price

When considering energy efficiency, the choice of fiber laser cutting machine is paramount. Fiber lasers are known for their superior energy conversion rates compared to traditional CO2 lasers, making them ideal for manufacturers seeking to minimize power consumption and operational costs. ZLTECH’s fiber laser cutting machines are designed with efficiency in mind, offering high-speed cutting capabilities while consuming less energy.

Another important consideration is laser cutting machine price. While energy-efficient machines may have a higher upfront cost, the long-term savings in energy bills and maintenance often outweigh the initial investment. ZLTECH provides transparent pricing and expert guidance, helping clients choose the best machine for their budget and sustainability goals.

Tips for Maximizing Energy Efficiency in Sheet Metal Laser Cutting

- Regularly maintain your laser cutting machines to ensure optimal performance and energy use.

- Train operators to use machines efficiently, including proper settings for different materials.

- Invest in fiber laser technology for higher energy conversion rates.

- Utilize automation and IoT solutions for real-time monitoring and control.

- Choose machines with adaptive energy management features.

Conclusion: Building a Sustainable Future with ZLTECH

Energy efficiency is no longer a luxury—it is a necessity for modern sheet metal laser cutting operations. By choosing energy-efficient machines from ZLTECH Laser Machine Factory, manufacturers can reduce costs, enhance productivity, and contribute to a cleaner environment. Whether you are looking for the latest fiber laser cutting machine or seeking competitive laser cutting machine price options, ZLTECH is your trusted partner for sustainable manufacturing solutions.

Contact us today to learn more about our energy-efficient laser cutting machines and discover how we can help you achieve your production and sustainability goals.

| Feature | Benefit |

|---|---|

| Fiber Laser Technology | High energy efficiency, lower operational costs |

| Intelligent Control Systems | Adaptive energy management, extended machine life |

| Automation Integration | Reduced waste, improved productivity |

| Transparent Pricing | Better ROI, budget-friendly options |