Why Is Tube Laser Cutting Machine Ideal for Stainless Steel Cutting?

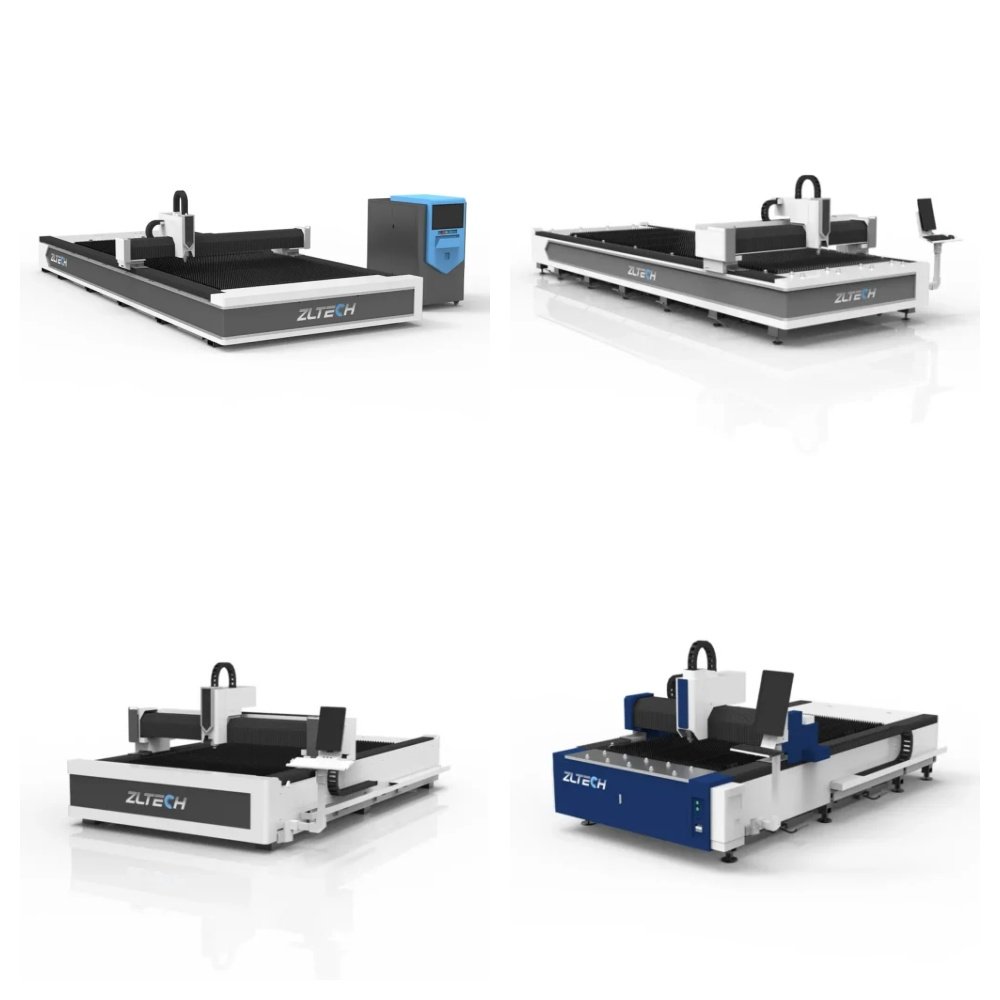

ZLTECH, a leading Laser Machine Factory, is dedicated to providing advanced solutions for the metal fabrication industry. Among our innovative offerings, the Tube Laser Cutting Machine stands out as a premier choice for stainless steel processing. In this article, we’ll explore why these machines are the preferred option for stainless steel cutting and how they can transform your manufacturing workflow.

Understanding the Tube Laser Cutting Machine

A Tube Laser Cutting Machine is a specialized piece of equipment designed for precision cutting of metal tubes and pipes, including stainless steel, carbon steel, aluminum, and more. Unlike traditional cutting methods, laser technology uses a focused beam of light to achieve high-precision cuts with minimal material wastage. ZLTECH’s machines leverage the latest fiber laser technology, ensuring both speed and accuracy.

- High precision and repeatability

- Minimal thermal deformation

- Versatile cutting capabilities

- Automated loading and unloading options

The Challenges of Cutting Stainless Steel

Stainless steel is renowned for its strength, corrosion resistance, and attractive finish, making it a preferred material across industries such as construction, automotive, food processing, and medical equipment. However, its durability also presents unique challenges when it comes to cutting:

- Hardness: Stainless steel is harder than many other metals, making traditional cutting methods slow and prone to tool wear.

- Heat Sensitivity: Excessive heat can cause discoloration, warping, or even compromise the integrity of the material.

- Precision Requirements: Many applications require intricate designs and tight tolerances, which traditional methods often struggle to achieve.

This is where ZLTECH’s Tube Laser Cutting Machine excels.

Advantages of Tube Laser Cutting Machine for Stainless Steel

1. Exceptional Cutting Precision

Laser cutting achieves unmatched accuracy, with tolerances as tight as +/- 0.1 mm. This is crucial for stainless steel components that require intricate shapes or detailed features. ZLTECH machines utilize advanced CNC systems to ensure every cut is consistent, regardless of batch size.

2. Clean, Burr-Free Edges

One of the standout benefits is the quality of the cut edge. Laser-cut stainless steel exhibits smooth, burr-free edges, minimizing the need for secondary finishing processes. This not only saves time but also reduces labor costs.

3. Minimal Heat-Affected Zone

Traditional cutting methods generate significant heat, which can alter the properties of stainless steel. Fiber lasers, as used in ZLTECH’s machines, concentrate energy in a small area, resulting in a minimal heat-affected zone. This preserves the material’s mechanical properties and surface finish.

4. High-Speed Production

Speed is a critical factor in modern manufacturing. A Tube Laser Cutting Machine can process stainless steel tubes at remarkable speeds, thanks to powerful laser sources and efficient motion systems. This leads to higher throughput and faster delivery times for your customers.

5. Versatility Across Tube Sizes and Shapes

ZLTECH’s machines are designed to handle a wide range of tube diameters, wall thicknesses, and profiles, including round, square, rectangular, and custom shapes. This flexibility makes them suitable for both standard and complex projects.

6. Reduced Material Waste

Laser cutting is a non-contact process, meaning there’s no tool wear and less risk of material distortion. The precision of the laser also allows for tight nesting of parts, maximizing material utilization and reducing scrap.

Sheet And Tube Laser Cutting Machine: Enhanced Flexibility

For manufacturers seeking even greater flexibility, ZLTECH offers the Sheet And Tube Laser Cutting Machine. This hybrid system is capable of processing both flat sheets and tubular materials, making it an ideal choice for workshops handling diverse fabrication tasks. With a single investment, you can expand your production capabilities and respond to a broader range of customer needs.

- Seamless switching between sheet and tube cutting modes

- Integrated software for easy design and programming

- Space-saving design for efficient factory layouts

Applications of Tube Laser Cutting Machine in Stainless Steel Fabrication

Laser cutting technology is transforming industries that rely on stainless steel components. Here are a few examples of where ZLTECH’s machines make a difference:

- Architectural Structures: Custom railings, frameworks, and decorative elements

- Automotive: Exhaust systems, chassis components, and roll cages

- Medical Equipment: Surgical instruments, hospital furniture, and machine frames

- Food Processing: Hygienic conveyor systems, enclosures, and storage racks

Why Choose ZLTECH as Your Laser Machine Factory?

As a trusted Laser Machine Factory, ZLTECH is committed to delivering machines that combine performance, reliability, and value. Here’s what sets us apart:

- Advanced Technology: We use the latest fiber laser sources and automation systems.

- Customization: Machines can be tailored to your specific production needs.

- Comprehensive Support: From installation to training and after-sales service, our team is with you every step of the way.

- Global Reach: ZLTECH serves clients worldwide, ensuring timely delivery and support.

Maintenance and Longevity

Stainless steel cutting can be tough on machinery, but ZLTECH’s Tube Laser Cutting Machine is engineered for durability and ease of maintenance. Key components are sourced from reputable brands, and modular designs make servicing straightforward. Regular maintenance ensures years of reliable operation, maximizing your return on investment.

Conclusion: Elevate Your Stainless Steel Cutting with ZLTECH

In today’s competitive manufacturing landscape, precision, speed, and versatility are non-negotiable. ZLTECH’s Tube Laser Cutting Machine and Sheet And Tube Laser Cutting Machine deliver all these advantages, making them the ideal solution for stainless steel fabrication. Whether you’re producing architectural elements, automotive parts, or medical equipment, our machines empower you to achieve superior results while optimizing costs and efficiency.

Ready to take your stainless steel cutting to the next level? Contact ZLTECH, your trusted Laser Machine Factory, and discover how our advanced solutions can revolutionize your production line.

Tags:CNC Hydraulic Press Brake,laser equipment factory,laser machine manufacturer,Sheet And Tube Laser Cutting Machine