The Ultimate Guide to Laser Marking: Applications, Techniques, and Benefits

Laser marking has revolutionized the way products are identified, labeled, and customized across various industries. From automotive parts to consumer electronics, laser marking offers unparalleled precision, permanence, and versatility. In this comprehensive guide, we'll delve into the world of laser marking, exploring its applications, techniques, and the myriad benefits it brings to businesses worldwide.

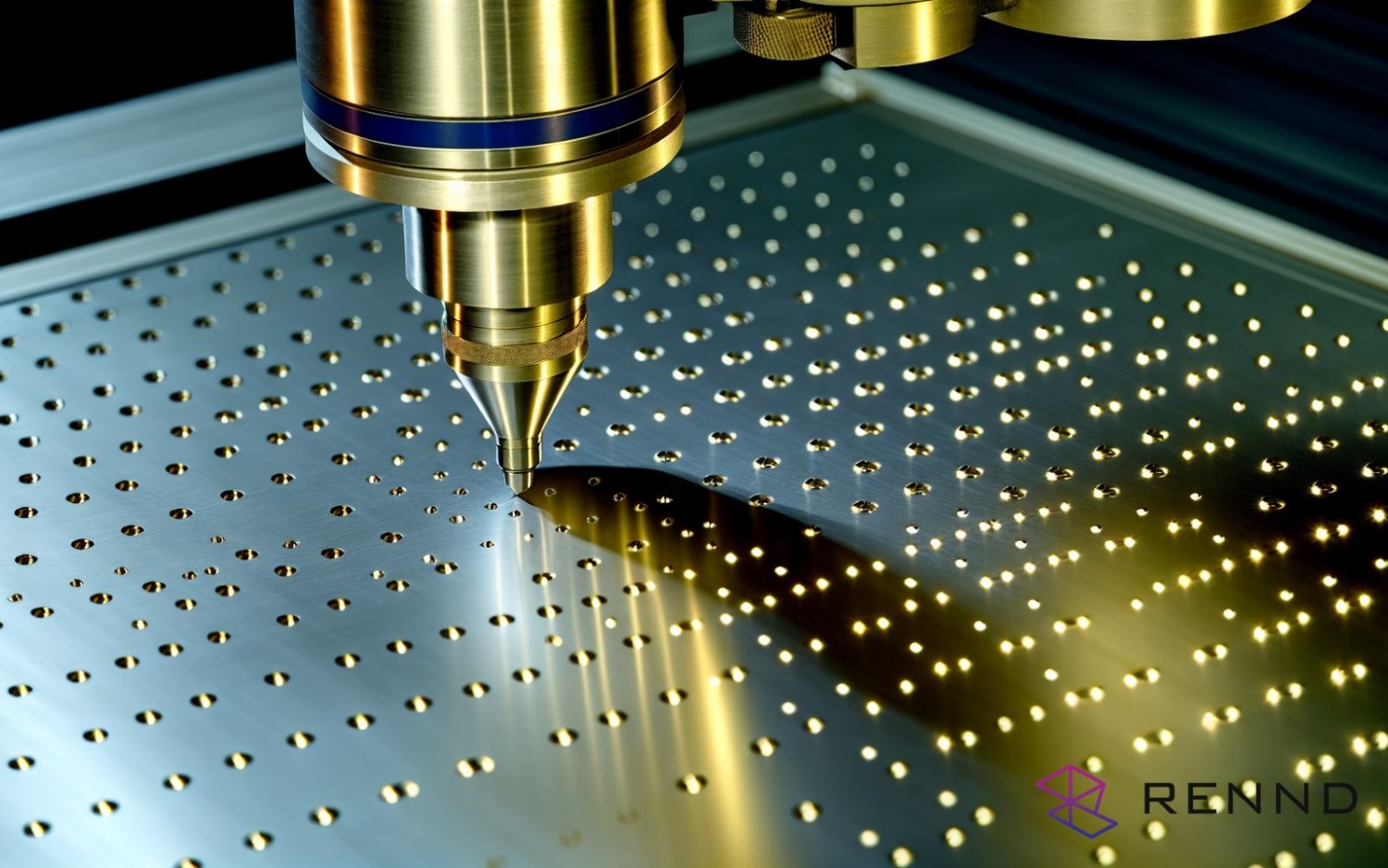

What is Laser Marking?

Laser marking is a non-contact, permanent marking process that uses a laser beam to create high-contrast marks on a wide range of materials. Unlike traditional marking methods such as inkjet printing or mechanical engraving, laser marking offers precise, clean, and durable marks without causing damage to the substrate.

Applications of Laser Marking

Laser marking finds applications across a multitude of industries, including:

Automotive: Marking serial numbers, logos, and barcodes on automotive components for traceability and quality control.

Electronics: Engraving identification codes, logos, and part numbers on electronic components for branding and anti-counterfeiting purposes.

Medical Devices: Laser marking surgical instruments, implants, and medical devices with unique identifiers for tracking and regulatory compliance.

Aerospace: Marking part numbers, serial numbers, and lot codes on aerospace components for inventory management and maintenance tracking.

Packaging: Creating date codes, batch numbers, and product identifiers on packaging materials for product traceability and anti-tampering measures.

Jewelry: Engraving intricate designs, logos, and text on jewelry pieces for personalization and branding.

Laser Marking Techniques

Laser marking techniques vary depending on the material being marked and the desired outcome. Some common techniques include:

Surface Annealing: Heating the surface of metals to create a permanent mark without removing material, ideal for high-contrast, durable marks on stainless steel and titanium.

Surface Etching: Removing a thin layer of material from the surface to create a contrasting mark, suitable for plastics, ceramics, and coated metals.

Foaming: Inducing a controlled chemical reaction to create a raised, frosted mark on plastics and polymers, commonly used for aesthetic and branding purposes.

Color Change: Utilizing laser energy to alter the color of materials such as anodized aluminum or certain plastics, creating high-contrast, multi-color marks.

Carbonization: Burning organic materials such as wood or leather to create dark, contrasting marks without removing material, popular for artistic and decorative applications.

Benefits of Laser Marking

Laser marking offers numerous advantages over traditional marking methods, including:

Permanent and High-Contrast Marks: Laser marks are resistant to wear, fading, and smudging, ensuring long-term legibility and durability.

Non-Contact Process: Laser marking does not require direct contact with the material, minimizing the risk of damage or contamination.

High Precision and Versatility: Laser marking offers precise control over mark depth, width, and placement, making it suitable for intricate designs and fine detail work.

Fast and Efficient: Laser marking is a fast and efficient process, capable of marking multiple parts simultaneously with minimal setup time.

Environmentally Friendly: Laser marking is a clean, non-toxic process that produces minimal waste and emissions, making it environmentally sustainable.

Conclusion

Laser marking has become an indispensable tool for product identification, branding, and customization in today's competitive marketplace. From automotive to aerospace, electronics to jewelry, laser marking offers unmatched precision, permanence, and versatility across a wide range of materials and applications. By understanding the fundamentals of laser marking, exploring its techniques, and embracing its benefits, businesses can elevate their products and gain a competitive edge in their respective industries.

For more information on laser marking solutions and to explore our range of high-quality laser equipment, visit MartLaser.com. Our experts are here to help you find the perfect laser marking solution to meet your business needs.

Recent Posts

Comprehensive Laser Machine Service: Ensuring Optimal Performance and Longevity

Essential Laser Machine Accessories: Maximizing Efficiency and Precision

Solid State Lasers: Revolutionizing Precision and Power in Modern Applications

Enhancing Precision: A Comprehensive Guide to Laser Lenses and Their Applications

Advancing Healthcare: A Comprehensive Guide to Laser Medical Equipment

Revolutionizing Manufacturing: A Comprehensive Guide to Laser 3D Printing Technology

The Power of Precision: A Comprehensive Guide to Laser Cleaning Technology

MARTLASER.COM, your reliable B2B2C sourcing center!

One-stop destination for all your laser shopping needs for B2B2C with great quality and competitive price.