Can a Fiber Laser Cutting Machine Reduce Material Waste?

ZLTECH, a leading Laser Machine Factory, is at the forefront of providing advanced fiber laser cutting solutions. As industries strive to optimize production and minimize costs, reducing material waste has become a critical focus. In this article, we will explore whether a fiber laser cutting machine can truly reduce material waste, and how ZLTECH’s innovative technology is making a significant impact.

Understanding Material Waste in Manufacturing

Material waste is an inevitable part of most manufacturing processes. Whether working with metals, plastics, or composites, traditional cutting methods like mechanical shearing, punching, or plasma cutting often leave behind considerable offcuts and unusable remnants. These inefficiencies not only increase raw material costs but also contribute to environmental concerns.

handheld laser cleaning machine

handheld laser cleaning machine

handheld laser welding machine

hydraulic press brake

sheet fiber laser cutting machine

fiber laser marking machine

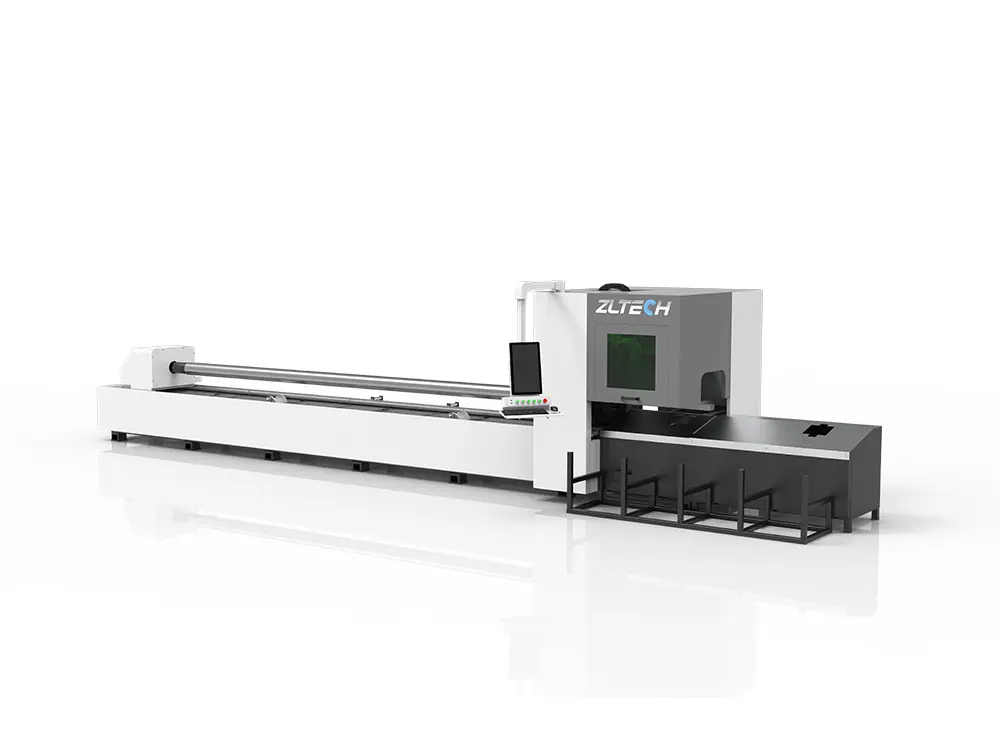

tube laser cutting machine

Reducing waste is essential for both economic and ecological reasons. Manufacturers are continuously seeking technologies that can help them achieve cleaner cuts, tighter tolerances, and more efficient use of materials. This is where fiber laser cutting machines come into play.

How Fiber Laser Cutting Machines Work

A fiber laser cutting machine uses a high-powered laser beam, delivered through optical fibers, to cut through various materials with extreme precision. The focused beam melts, burns, or vaporizes the material, resulting in a clean and accurate cut. ZLTECH’s Laser Machine Factory has engineered their machines to deliver superior performance, even on complex or intricate designs.

- High Precision: Fiber lasers can achieve extremely fine cuts, reducing the width of the kerf (cutting gap) and maximizing material usage.

- Minimal Heat Affected Zone: The concentrated energy reduces thermal distortion, allowing parts to be nested closer together.

- Automated Nesting Software: Advanced programming enables optimal arrangement of parts, further reducing waste.

The Role of ZLTECH in Waste Reduction

ZLTECH has invested heavily in research and development to ensure their fiber laser cutting machines are equipped with the latest technology. Their machines feature intelligent nesting algorithms and real-time monitoring systems, which contribute to efficient material utilization.

By collaborating with clients across automotive, aerospace, and electronics industries, ZLTECH’s Laser Machine Factory has gathered extensive data on material waste reduction. Their findings consistently show that fiber laser cutting machines can reduce scrap rates by up to 30% compared to traditional methods.

Key Advantages of Fiber Laser Cutting for Material Waste Reduction

- Precision Cutting: The narrow beam width allows for intricate patterns and tight part placement, minimizing offcuts.

- Flexible Production: Quick reprogramming enables manufacturers to optimize layouts for every batch, reducing leftover material.

- Consistent Quality: Automated controls ensure repeatable results, so every part is cut to specification with minimal error.

- Reduced Secondary Processing: Smooth edges and clean cuts eliminate the need for additional finishing, saving more material.

Comparing Fiber Laser Cutting with Other Methods

| Cutting Method | Material Waste | Precision | Flexibility |

|---|---|---|---|

| Mechanical Shearing | High | Low | Low |

| Plasma Cutting | Moderate | Moderate | Moderate |

| Fiber Laser Cutting | Low | High | High |

This comparison highlights the clear advantage of fiber laser cutting in reducing material waste while also offering superior precision and flexibility.

Environmental and Economic Benefits

By reducing material waste, manufacturers can lower their raw material costs and improve their profit margins. Additionally, less waste means fewer resources are consumed, and fewer scraps end up in landfills. This aligns with global trends toward sustainable manufacturing and environmental responsibility.

ZLTECH’s Laser Machine Factory has helped clients achieve significant cost savings and reduce their carbon footprint by implementing fiber laser cutting technology. These benefits are particularly important for industries facing strict environmental regulations or seeking to enhance their corporate social responsibility profiles.

Integration with Automation and Smart Manufacturing

Modern fiber laser cutting machines from ZLTECH are designed for seamless integration with factory automation systems. This includes robotics for material handling, smart sensors for quality control, and cloud-based analytics for process optimization. Such integration not only boosts productivity but also ensures that material usage is tracked and optimized in real-time.

By leveraging Industry 4.0 principles, ZLTECH enables manufacturers to further reduce waste and increase efficiency throughout the entire production process.

Case Study: ZLTECH’s Impact on Material Waste Reduction

One of ZLTECH’s clients in the automotive sector reported a 25% reduction in material waste after switching to fiber laser cutting machines from traditional plasma cutters. The company was able to nest more parts per sheet, reduce scrap, and lower their overall production costs. Additionally, the improved cut quality reduced the need for secondary operations, saving even more material and labor.

Laser Machine Factory: Your Partner in Sustainable Manufacturing

As a trusted Laser Machine Factory, ZLTECH is committed to helping manufacturers achieve their sustainability and efficiency goals. Their fiber laser cutting machines are built for reliability, precision, and minimal waste. With ongoing support and customization options, ZLTECH ensures that every client can maximize their material usage and minimize their environmental impact.

Conclusion: The Future of Material Waste Reduction

In summary, a fiber laser cutting machine from ZLTECH can significantly reduce material waste compared to traditional cutting methods. The combination of precision, automation, and smart software makes it possible to optimize every aspect of the cutting process. As manufacturers continue to seek ways to improve efficiency and sustainability, fiber laser cutting technology will play an increasingly vital role.

If you are looking to reduce material waste, lower costs, and enhance your manufacturing capabilities, consider partnering with ZLTECH’s Laser Machine Factory. With their expertise and state-of-the-art fiber laser cutting machines, you can achieve both economic and environmental benefits.

Keywords: fiber laser cutting machine, Laser Machine Factory