In the rapidly evolving world of manufacturing, technology has become a cornerstone of innovation and efficiency. Among the myriad of advanced tools and equipment, laser machines stand out as pivotal instruments driving progress across various industries. Behind these sophisticated devices are laser machine manufacturers, whose role is indispensable in shaping the future of production processes. This blog explores the significance of laser machine manufacturers and underscores their critical contributions to technological advancements and economic growth.

Revolutionizing Precision and Accuracy

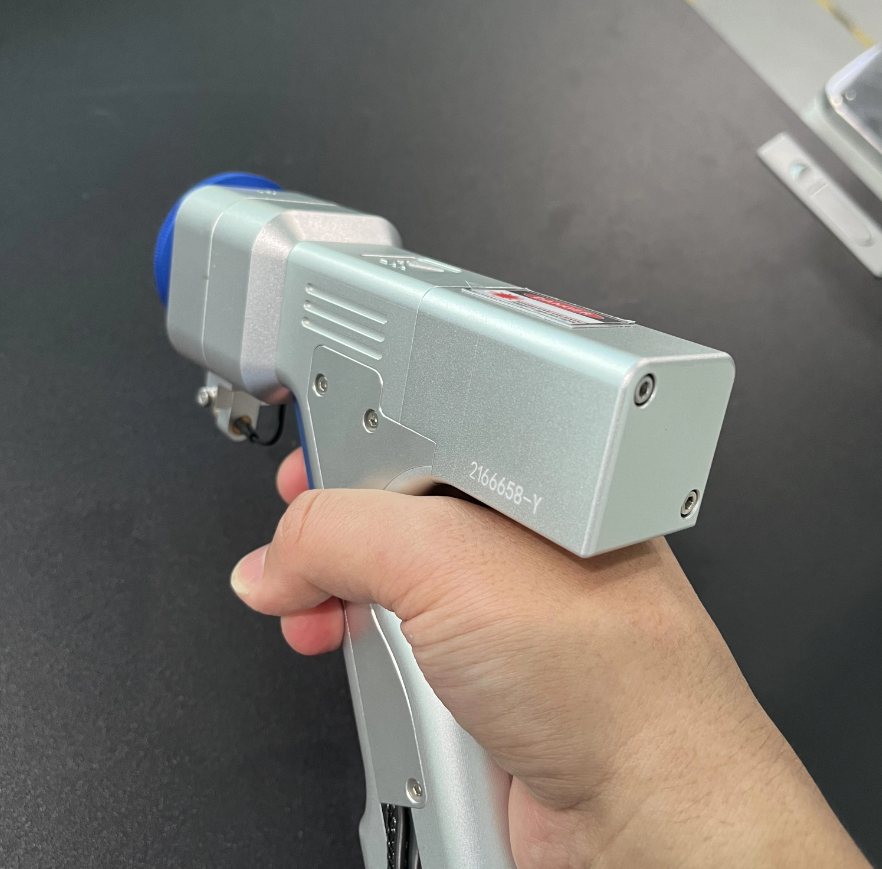

Laser machines have revolutionized the way we manufacture products by offering unparalleled precision and accuracy. Whether it’s in the automotive industry, aerospace, electronics, or medical fields, the need for meticulous craftsmanship is paramount. Laser machine manufacturers are at the forefront of this precision revolution, designing and engineering machines capable of cutting, welding, engraving, and marking materials with sub-micron accuracy. This level of detail is essential for creating complex components and assemblies that meet stringent quality standards and regulatory requirements.

The importance of precision extends beyond aesthetic perfection; it ensures the functional integrity and safety of the end products. For instance, in the aerospace industry, where parts must withstand extreme temperatures and pressures, any deviation in dimensions can compromise the overall performance and safety of the aircraft. Laser machines, with their unwavering precision, are instrumental in producing components that meet these rigorous specifications.

Enhancing Efficiency and Productivity by Laser Machine Manufacturer

In an era where time is money, efficiency is a critical factor determining the success of manufacturing operations. Laser machine manufacturers play a pivotal role in enhancing productivity by providing machines that can operate at high speeds with minimal downtime. These machines can process a wide range of materials, from metals and plastics to ceramics and glass, with remarkable speed and consistency.

Moreover, laser technology eliminates the need for traditional tools and fixtures, reducing setup time and speeding up the transition between different products. This flexibility allows manufacturers to adapt quickly to market demands and produce a wider variety of products without significant capital investments. The result is a more agile and responsive production system that can capitalize on emerging trends and opportunities.

Promoting Sustainability and Environmental Responsibility

Sustainability is a growing concern for businesses and consumers alike. Laser machine manufacturers are playing a crucial role in promoting environmentally friendly manufacturing practices. Laser cutting and welding processes generate minimal waste and emit fewer harmful emissions compared to traditional methods. Additionally, laser machines can be powered by renewable energy sources, such as solar or wind power, further reducing their carbon footprint.

Moreover, laser technology enables manufacturers to optimize material usage by precisely cutting and shaping materials with minimal waste. This not only conserves resources but also reduces disposal costs, making the production process more economically and environmentally viable.

Fostering Innovation and Technological Advancement

Laser machine manufacturers are constantly pushing the boundaries of technology, developing new applications and refining existing processes. Their relentless pursuit of innovation is crucial for driving progress across various industries. By investing in research and development, these manufacturers are able to introduce new laser technologies that address emerging challenges and capitalize on untapped opportunities.

For example, advancements in laser additive manufacturing (LAM), also known as 3D printing, are enabling manufacturers to produce complex, lightweight structures with unprecedented precision and efficiency. This technology is transforming industries such as aerospace, automotive, and healthcare by enabling the creation of customized parts and prototypes that were previously impossible to make.

Conclusion

In conclusion, laser machine manufacturers are essential players in the global manufacturing landscape. Their contributions to precision, efficiency, sustainability, and innovation are indispensable for driving progress and fostering economic growth. As technology continues to evolve, the role of these manufacturers will become even more critical in shaping the future of manufacturing. By embracing innovation and staying ahead of the curve, they will continue to play a pivotal role in transforming industries and improving our lives.