In industries where product safety, regulatory compliance, and supply chain efficiency are paramount, laser marking for traceability has become an essential solution. This advanced technology allows manufacturers to apply permanent and precise markings—such as barcodes, serial numbers, and batch information—directly onto packaging materials. By ensuring clear and durable identification, laser marking plays a critical role in enabling seamless tracking and monitoring from production through to the end-user. In this post, we’ll explore how laser marking enhances traceability in packaging, helping businesses meet industry standards while improving operational efficiency.

Understanding Laser Marking

Laser marking for traceability is a technology that uses a focused laser beam to create permanent marks on a variety of materials, commonly used for applications such as product identification, branding, and traceability in packaging.

Unlike laser cutting, which removes material to separate parts, or laser engraving, which etches deeper into the surface, laser marking alters the material’s surface through laser processes like discoloration, foaming, or carbonization. This allows for high-precision permanent markings such as serial numbers, barcodes, logos, and expiration dates. In effect, you are creating your own laser labelling for your products, that is typically as durable as the product being marked.

There are several types of laser marking, including annealing, which changes the colour of metal surfaces; carbon migration, which darkens the surface of metals; foaming, which creates raised markings on plastics; and etching, which produces shallow grooves. Each type is suited to specific materials and applications, making laser marking a versatile and reliable solution across various industries.

The Importance of Traceability in Packaging

Traceability in the packaging industry is the ability to track and trace products throughout the supply chain, ensuring that every item can be identified and monitored from production to the end consumer. This is especially crucial in industries like pharmaceuticals, food, and electronics, where safety, quality, and authenticity are paramount.

Traceability enhances quality control, enables efficient recalls, ensures regulatory compliance, and prevents counterfeiting. Laser marking plays a key role in achieving traceability by providing unique, permanent, and easily readable marks on packaging. These marks ensure that products are accurately identified, supporting the integrity and transparency of the supply chain.

Choosing the Right Laser Marking Systems

Choosing the right laser marking system for packaging requires careful consideration of several factors to ensure optimal performance and efficiency. The type of material to be marked is crucial, as different lasers are suited to different substrates, whether it’s plastic, metal, or paper. Mark quality is another key factor, as the laser must produce clear, precise marks that meet industry standards.

Speed is also important, especially in high-volume production environments where efficiency is critical. Additionally, the production environment itself—such as temperature, humidity, and cleanliness—can affect the choice of laser system.

By considering these factors, businesses can select a laser marking system that meets their specific packaging needs and enhances overall production quality.

Laser Marking vs. Traditional Methods

When it comes to marking materials for identification, branding, or compliance, the choice between laser marking and traditional marking methods is crucial. Each approach has its own set of advantages and disadvantages, which vary depending on the application, material, and industry.

Traditional Marking Methods: An Overview

Traditional marking methods include techniques like inkjet printing, embossing, and stamping.

- Inkjet Printing: This method uses a stream of ink droplets to create marks on the surface of a material. It’s commonly used for printing expiration dates, barcodes, and batch numbers on packaging. While inkjet printing is relatively fast and can be used on a variety of surfaces, the marks it creates are often less durable and can fade or smudge over time.

- Embossing: Embossing involves creating a raised or recessed design on the surface of a material, typically using a die and pressure. This method is frequently used for branding or decorative purposes on paper, plastic, or metal. While embossing is highly durable and adds a tactile quality, it can be time-consuming and is limited in its ability to produce detailed or intricate designs.

- Stamping: Stamping uses a die to imprint or indent a design onto a material. It’s a versatile technique used across industries for marking parts or products. Stamping is known for its durability and speed but lacks the precision needed for intricate designs or small-scale text.

Comparing Laser Marking and Traditional Methods

Durability: Laser marking stands out for its exceptional durability. Unlike inkjet printing, which is prone to fading, laser markings are permanent and resistant to wear, chemicals, and environmental factors. Embossing and stamping are also durable, but they can alter the material’s structure, which is not always desirable.

Precision: Laser marking offers unparalleled precision, capable of creating intricate designs, fine text, and detailed logos with high accuracy. This level of detail is challenging to achieve with embossing or stamping and impossible with inkjet printing, which is limited by the resolution of the print head.

Speed: In terms of speed, inkjet printing and laser marking are both fast, but laser marking often edges out due to its ability to rapidly create high-quality marks without the need for consumables like ink. Embossing and stamping, while relatively quick, often require setup and tooling time, which can slow down production.

Cost-Effectiveness: Traditional methods like inkjet printing are initially cheaper due to lower equipment costs. However, over time, the cost of consumables (ink, dies) and maintenance can add up. Laser marking, despite higher upfront costs, tends to be more cost-effective in the long run due to minimal maintenance and the absence of consumables.

Environmental Impact: Laser marking is more environmentally friendly compared to traditional methods. It doesn’t require inks, chemicals, or additional materials, leading to less waste and fewer emissions. Inkjet printing, on the other hand, involves chemical inks that can be harmful if not disposed of properly, and embossing/stamping often requires significant energy and material resources.

When Laser Marking is Superior

Certain industries and applications clearly benefit from the unique advantages of laser marking.

- Electronics: The precision of laser marking is ideal for etching small, detailed codes or logos on electronic components where space is limited and clarity is essential.

- Medical Devices: In the medical field, laser marking is preferred for its ability to create highly detailed and durable marks that can withstand sterilization processes without degrading.

- Automotive: In automotive manufacturing, where parts must endure harsh environments, laser marking provides long-lasting identification that won’t wear off over time.

- Aerospace: The aerospace industry relies on laser marking for its ability to produce precise, readable, and permanent markings on critical components, ensuring traceability and compliance with stringent safety standards.

In conclusion, while traditional marking methods like inkjet printing, embossing, and stamping have their places, laser marking offers distinct advantages in terms of durability, precision, speed, cost-effectiveness, and environmental impact, making it the superior choice for many modern industrial applications.

Best Practices for Implementing Laser Marking for Traceability in Packaging

Implementing a laser marking system for traceability in packaging can significantly enhance your production line’s efficiency, accuracy, and compliance. To maximize the benefits, it’s crucial to approach the process strategically, from planning and setup to ongoing maintenance. Below are the best practices to ensure a successful implementation.

1. Conduct a Thorough Needs Assessment

Before diving into the setup, it’s essential to conduct a comprehensive needs assessment. This step will help you identify the specific requirements of your packaging process, such as:

- Material Types: Determine the materials used in your packaging. Different materials (plastics, metals, glass, etc.) may require different laser technologies (CO2, fiber, or UV lasers).

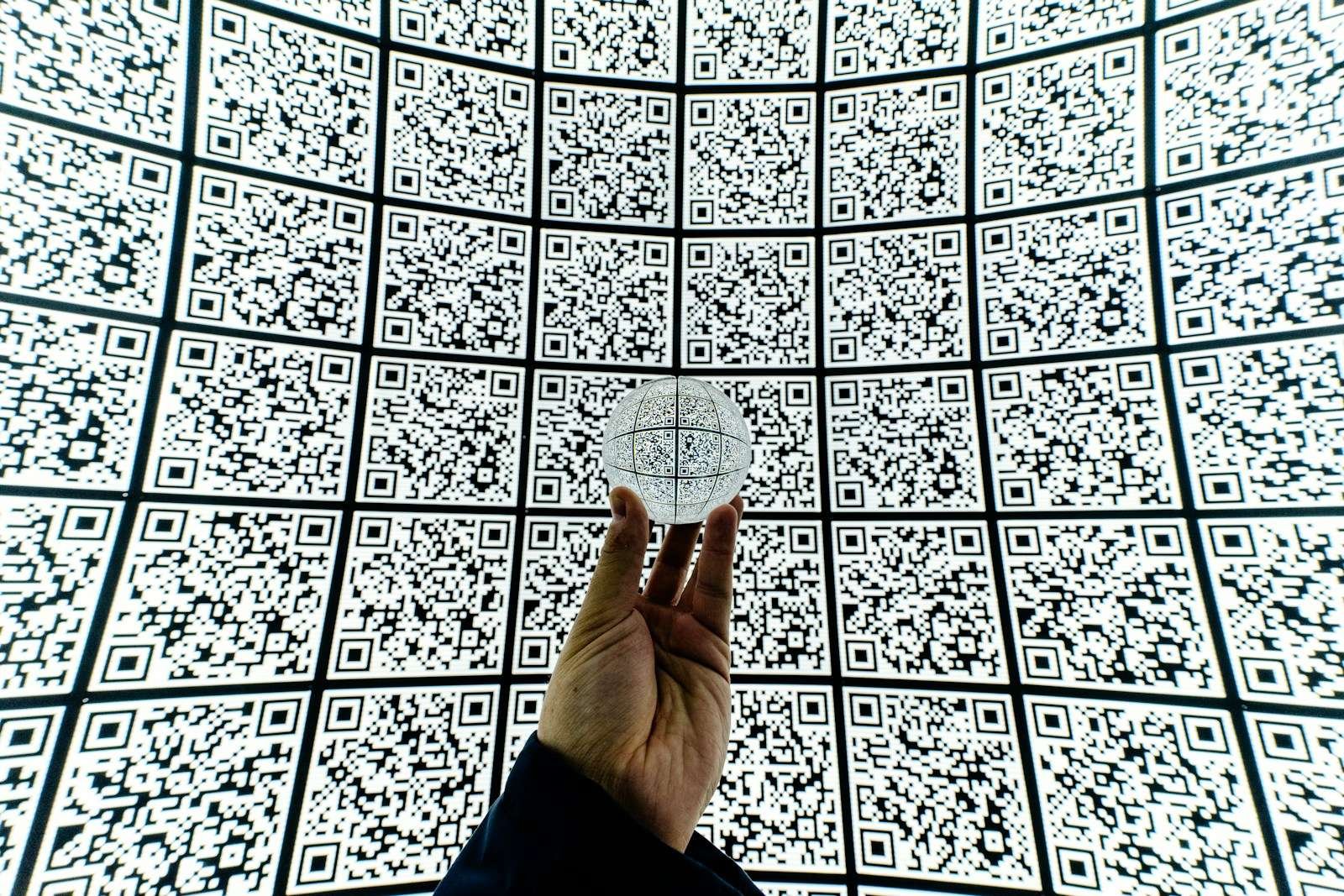

- Marking Requirements: Define what needs to be marked, such as barcodes, QR codes, serial numbers, or logos. The level of detail and the desired durability of the mark will influence the choice of laser system.

- Production Volume: Assess your production speed and volume to ensure the laser marking system can keep pace without bottlenecking the line.

- Regulatory Compliance: Consider industry-specific regulations that may dictate the type, placement, and legibility of the markings.

A clear understanding of these factors will guide you in selecting the most appropriate laser marking system for your needs.

2. Plan the System Setup

Once you’ve completed your needs assessment, the next step is planning the laser marking system’s setup. This involves several key considerations:

- System Selection: Choose a laser marking system that matches your specific requirements. For example, CO2 lasers are ideal for organic materials like paper and wood, while fiber lasers are better suited for metals and plastics.

- Integration with Existing Equipment: Ensure the laser marking system can seamlessly integrate with your existing production line. This may involve configuring conveyors, sensors, and control systems to work in tandem with the laser.

- Workspace Layout: Design the layout of your workspace to optimize the flow of materials and ensure easy access to the laser marking system for maintenance and troubleshooting.

3. Emphasize Staff Training and Safety Protocols

Proper staff training and adherence to safety protocols are crucial for the efficient and safe operation of a laser marking system.

- Training: Train your operators on how to use the laser marking equipment, including setting up jobs, adjusting parameters, and performing routine checks. Ensure they understand the importance of maintaining the correct focus, speed, and power settings for consistent results.

- Safety Measures: Implement safety protocols to protect operators from potential hazards such as laser exposure and fumes. This includes providing appropriate personal protective equipment (PPE), such as safety glasses, and ensuring the workspace is equipped with proper ventilation and safety interlocks.

- Emergency Procedures: Establish clear procedures for responding to emergencies, such as equipment malfunctions or accidental exposure to the laser beam.

4. Maintain and Troubleshoot the Equipment

Regular maintenance and prompt troubleshooting are essential for keeping your laser marking system running smoothly and ensuring consistent performance.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule, which typically includes cleaning lenses, checking and replacing filters, and ensuring that the laser’s cooling system is functioning properly. Regular maintenance helps prevent unplanned downtime and extends the life of the equipment.

- Troubleshooting: Develop a troubleshooting guide for common issues, such as inconsistent marking quality, alignment problems, or software glitches. Train your staff to recognize early signs of trouble, such as unusual noises or error messages, and to take appropriate action.

- Software Updates: Keep your laser marking software up to date to benefit from the latest features and security enhancements. Regular updates can also improve system stability and compatibility with new materials or production processes.

5. Monitor and Optimize Performance

After implementation, continuously monitor the performance of your laser marking system. Track key metrics such as marking speed, error rates, and downtime. Use this data to identify areas for improvement, whether through adjusting settings, upgrading components, or refining operator training.

Regular audits of the traceability system can help ensure that it continues to meet regulatory requirements and industry standards, providing peace of mind that your packaging process is both efficient and compliant.

In conclusion, implementing laser marking for traceability in packaging requires careful planning, proper training, and ongoing maintenance. By following these best practices, you can ensure that your laser marking system operates safely and efficiently, delivering high-quality, durable marks that enhance traceability and support your business goals.

What about Laser Marking Services?

Laser marking services can come into their own when the end product is packaged inside a specific container such as used for sunglasses, ear pods, jewellery, etc. These containers can then be married up with the product at a later date. The laser marking of disposable packaging is usually best carried out on or close to the manufacturing line.

FAQs

What is Laser Marking for Traceability?

Laser marking for traceability is a process that uses a focused laser beam to create permanent markings, such as serial numbers, barcodes, QR codes, and other identifiers, directly onto products or packaging. Unlike traditional methods like ink printing or labels, laser marking is highly precise, durable, and resistant to wear. It ensures that key information remains clear and legible throughout a product’s lifecycle, making it essential for industries where tracking, compliance, and product identification are critical, such as in manufacturing, pharmaceuticals, and food packaging.

Laser marking for traceability is a process that uses a focused laser beam to create permanent markings, such as serial numbers, barcodes, QR codes, and other identifiers, directly onto products or packaging. Unlike traditional methods like ink printing or labels, laser marking is highly precise, durable, and resistant to wear. It ensures that key information remains clear and legible throughout a product’s lifecycle, making it essential for industries where tracking, compliance, and product identification are critical, such as in manufacturing, pharmaceuticals, and food packaging.

What is laser marking for packaging?

Laser marking for packaging is a process that uses a concentrated laser beam to permanently apply information such as product details, batch numbers, expiration dates, barcodes, and branding directly onto packaging materials. This method is highly precise and durable, ensuring that the markings are resistant to wear, smudging, and environmental factors. Laser marking is ideal for a variety of packaging materials, including plastic, glass, cardboard, and metal, making it a versatile solution for industries requiring high-quality, tamper-proof identification and traceability on their products.

Laser marking for packaging is a process that uses a concentrated laser beam to permanently apply information such as product details, batch numbers, expiration dates, barcodes, and branding directly onto packaging materials. This method is highly precise and durable, ensuring that the markings are resistant to wear, smudging, and environmental factors. Laser marking is ideal for a variety of packaging materials, including plastic, glass, cardboard, and metal, making it a versatile solution for industries requiring high-quality, tamper-proof identification and traceability on their products.

What is laser marking used for?

Laser marking is used to permanently apply information such as serial numbers, barcodes, QR codes, logos, and other identifiers onto a wide range of materials. It is commonly used in industries like manufacturing, electronics, automotive, medical devices, and packaging for purposes including product identification, traceability, branding, and compliance. The process is highly precise, allowing for detailed markings that are resistant to wear and environmental conditions, making it ideal for both aesthetic branding and critical information marking.

Laser marking is used to permanently apply information such as serial numbers, barcodes, QR codes, logos, and other identifiers onto a wide range of materials. It is commonly used in industries like manufacturing, electronics, automotive, medical devices, and packaging for purposes including product identification, traceability, branding, and compliance. The process is highly precise, allowing for detailed markings that are resistant to wear and environmental conditions, making it ideal for both aesthetic branding and critical information marking.

What is the process of laser marking plastic?

The process of laser marking plastic involves using a focused laser beam to create permanent marks on the surface of the plastic material. The laser interacts with the plastic by either engraving, discoloring, foaming, or carbonizing the surface, depending on the type of plastic and the desired outcome. The heat from the laser alters the material to produce high-contrast markings such as logos, barcodes, or text. This non-contact process is precise and quick, ensuring clean, legible, and durable marks without damaging the plastic’s integrity, making it ideal for a wide range of industrial and commercial applications.

The process of laser marking plastic involves using a focused laser beam to create permanent marks on the surface of the plastic material. The laser interacts with the plastic by either engraving, discoloring, foaming, or carbonizing the surface, depending on the type of plastic and the desired outcome. The heat from the laser alters the material to produce high-contrast markings such as logos, barcodes, or text. This non-contact process is precise and quick, ensuring clean, legible, and durable marks without damaging the plastic’s integrity, making it ideal for a wide range of industrial and commercial applications.